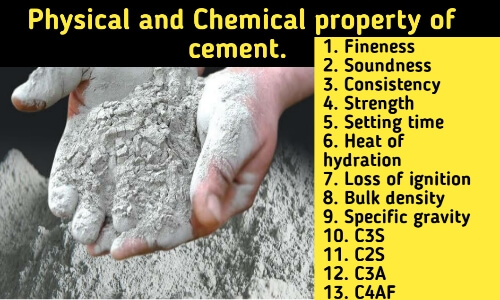

In this post, we explained the different types of properties of cement. Explain the physical properties of cement, chemical properties of cement. We also explain the properties of the cement bag which includes the weight of a cement bag, the volume of the cement bag, density and so more.

Table of Contents

Physical Properties Of Cement:

- Fineness

- Soundness

- Consistency

- Compressive strength

- Setting time

- Heat of hydration

- Loss of ignition

- Bulk density of cement

- Specific gravity of cement

1. Fineness property of cement:

Fineness is a size measure of cement particles. Generally, fineness indicates the size of the cement particles. Finer cement increases the heat of hydration of cement. And also causing a flash set of cement.

The fineness of cement is important for the rate of hydration. Finer cement offers greater surface area of cement hence cement getting strength rapidly

- Different cement grinding with different fineness.

- The smallest particle size of cement may have about 1.5 microns.

- The largest average size of the cement particles may be taken as about 10 microns.

- The fineness property of cement also affects the 28day strength of cement.

- Increase of fineness causing drying shrinkage cracks of cement.

- It is suggested that the 25 to 30% of cement particle size is less than 7mm.

The fineness property of cement determines by sieve analysis test and air permeability test. Click to know how these tests are performed actual in the field and lab.

ALSO READ : Field and Laboratory test on cement. most important for concrete durability.

2. Soundness properties of cement:

Soundness is referred to as a change of volume cement after its final setting. Generally, the best cement has less than 10mm expansion or shrink.

- The expansion of cement is a serious difficulty on structure durability.

- The unsoundness of cement is due to excess lime, inadequate burning of cement, not proper grinding, the high proportion of magnesium content or calcium sulfate content etc.

- For the unsoundness reason of cement, magnesia content is limited to less than 6% in cement.

- If the gypsum is more than 3 to 5% then it is combined with c3s and causing excessive expansion of cement after setting. Due to that the durability of the structure decrease.

Le chatelier’s test is performed To check soundness property of cement.

Click here to get knowledge about how to perform Le chatelier’s test in field and lab.

3. Consistency property of cement:

Consistency is the ability to flow cement paste in a normal condition. The consistency of cement is a measure of water required to make flowable cement paste and used easily in normal condition.

A standard consistency test is used to determine the consistency of cement. In this test, Vicat apparatus and plunger are used. The aim of this test is to determine the water requirement for dry cement paste to make it consistent.

4. Compressive strength of cement:

Compressive strength is the most important property of all properties of cement. Cement and concrete are always tested for strength properties and especially compressive strength. The grade of cement is to define the compressive strength of cement.

33 grade cement means cement gets 33N/mm2 strength after 28 days. 43 grade of cement says cement gets 43N/mm2 strength after 28 days. And 53 grade of cement says cement gets 53N/mm2 strength after 28 days.

Compressive strength is directly proportional to the durability of the structure. In cement mortar or cement concrete, cement provides maximum compressive strength due to its bonding. Which is make concrete or mortar durable.

To measure compressive test of cement compression test is taken by universal testing machine.

5. Setting time of cement.

Setting time of cement include two properties.

- Initial setting time.

- Final setting time.

Initial setting time of cement:

The initial setting time of cement is defined as the time at which cement paste is starting to gain hardening strength (reducing its plasticity) after adding water. Generally, the initial setting time of cement is lies between 30minute to 40minute.

Final setting time of cement:

The final setting time of cement is getting by performing the final setting time test on cement in which Vicat apparatus and circular attachment needle is used. The cement shall be considered as finally set when lower attachment of the needle does not show any impression on cement paste.

Generally the final setting time of cement is 10hours.

ALSO READ: What is ferrocement? material, method, application and uses.

6. Heat of Hydration:-

When water is added to cement then cement chemical compounds react with water this process is known as the hydration process of cement. Due to the hydration process of cement high quantity of heat is generated this heat is known as the heat of hydration.

Heat of hydration is very important in a mass construction like construction of dam etc.

As per research study has been observed that the interior temperature of large mass concrete is 50°C greater than the original temperature of the concrete mass at the time of placing and this high temperature is found to persist for a prolonged period.

The heat of hydration affected due to climatic conditions, the volume of cement, water-cement ratio, gypsum quantity, improper grinding of cement, cement chemical compounds and etc.

This factors affect the heat of hydration and causing flash set of cement and increase amount of heat of hydration.

7. Loss of ignition:

The cement losses its weight when it is heated 900 to 1000 degrees Celsius. This weight loss of cement is known as loss of ignition. Loss of ignition shows the pre hydration and carbonation of cement.

Pre hydration affects the initial setting time of cement and carbonation affects the strength of cement due to the durability of structure reduces.

8. Bulk density of cement:

Bulk density of cement is a mass of cement per unit volume in its natural state (including pores and air voids). The bulk density of cement is lies between 1000 kg/m3 to 1300 kg/m3.

9. Specific gravity of cement:

The specific gravity of cement is a ratio of a density of cement to a density of water. Generally, the specific gravity of cement lies between 2.8 to 3.2.

Chemical Properties of cement:

Chemical properties of cement is totally depend on chemical composition of cement.

| Approximate Oxide Composition Limits of Ordinary Portland Cement | |

| Oxide | Percent content |

| CaO | 60 – 67 |

| SiO3 | 17 – 25 |

| Al2O3 | 3 – 8 |

| Fe2O3 | 0.5 – 6 |

| MgO | 0.1 – 4.0 |

| Alkalis (K2O, Na2O) | 0.4 – 1.3 |

| SO3 | 1.3 – 3.0 |

Bogue’s Compound:

Bogue’s compound are the major chemical properties of cement. Here explain all of them.

- Tricalcium silicate

- Dicalcium silicate

- Tricalcium aluminates

- Tetracalcium aluminoferrite

| Bogue’s compound for cement | ||

| Name Of Compound | Formula | Abbreviated Formula |

| Tricalcium silicate | 3 CaO.SiO2 | C3S |

| Dicalcium silicate | 2 CaO.SiO2 | C2S |

| Tricalcium aluminate | 3 Cao.Al2O3 | C3A |

| Tetracalcium aluminoferrite | 4 CaO.Al2O3.Fe2O3 | C4AF |

1. Tricalcium silicate (c3s) :-

- Tricalcium of cement is responsible for early strength of concrete.

- First 7 days strength is due to tricalcium amount in cement.

- Tricalcium of cement produce more heat of hydration

- A cement with more tricalcium silicate content is better for cold weather concreting.

2. Diacalcium silicate (c2s) :-

- The hydration of dicalcium silicate starts after 7 days. Hence, it gives strength after 7 days.

- Diacalcium silicate hydrates and hardens slowly and provides much of the ultimate strength.

- Dicalcium is responsible for the later strength of concrete.

- Dicalcium produces less heat of hydration.

3. Tricalcium aluminate (C3A):-

- The reaction of tricalcium aluminate with water is very fast and may lead to an immediate stiffening of paste, and this process is termed as flash set.

- To prevent this flash set, 2 to 3% gypsum is added at the time of grinding the cement clinkers.

- The hydrated tricalcium aluminate do not contribute to the strength of concrete.

4. Tetracalcium aluminoferrite (C4AF):-

- Tetracalcium aluminoferrite causes rapid hydration of cement.

- Tetracalcium aluminoferrite not contribute to the strength of concrete.

- The hydrates of Tetracalcium aluminoferrite show a comparatively higher resistance to the sulfate attack than the hydrates of tricalcium aluminate.

Properties of cement bag:-

Properties of cement bag include all details of cement bag like the size of the cement bag, the volume of the cement bag, the weight of cement bag, description of cement bag and so more.

- Weight of cement bag: 50kg

- The volume of cement bag: 0.035 cubic meter

- Size of Cement bag: 30*20*4 (inches)

Marking on cement bag

- The words of the cement bag are clearly visible. The type of cement writes on the cement bag. the OPC Cement mention as an “Ordinary Portland Cement” “53” Grade.

- The manufacture’s name and its mark are written on the cement bag.

- Cement bag net quantity is write in kg.

- The word Use No Hooks, write and easily visible on the cement bag.

- Batch/control unit number is written in terms of week month and year packing.

- The cement bag consists Address of the manufacturer.

- The cement bag consists of BIS marking.

- Particular IS code no mentioned on the cement bag. Like OPC cement bag consist IS 12269-2013 on the bag.

ALSO READ : What is polymer concrete and sulphur infiltrated concrete.