In this post, we share what is Ferro cement? how to make Ferrocement? a constructed method, application of its in various sectors, advantages of its, who invented Ferrocement? and so more. What is Ferro Cement?

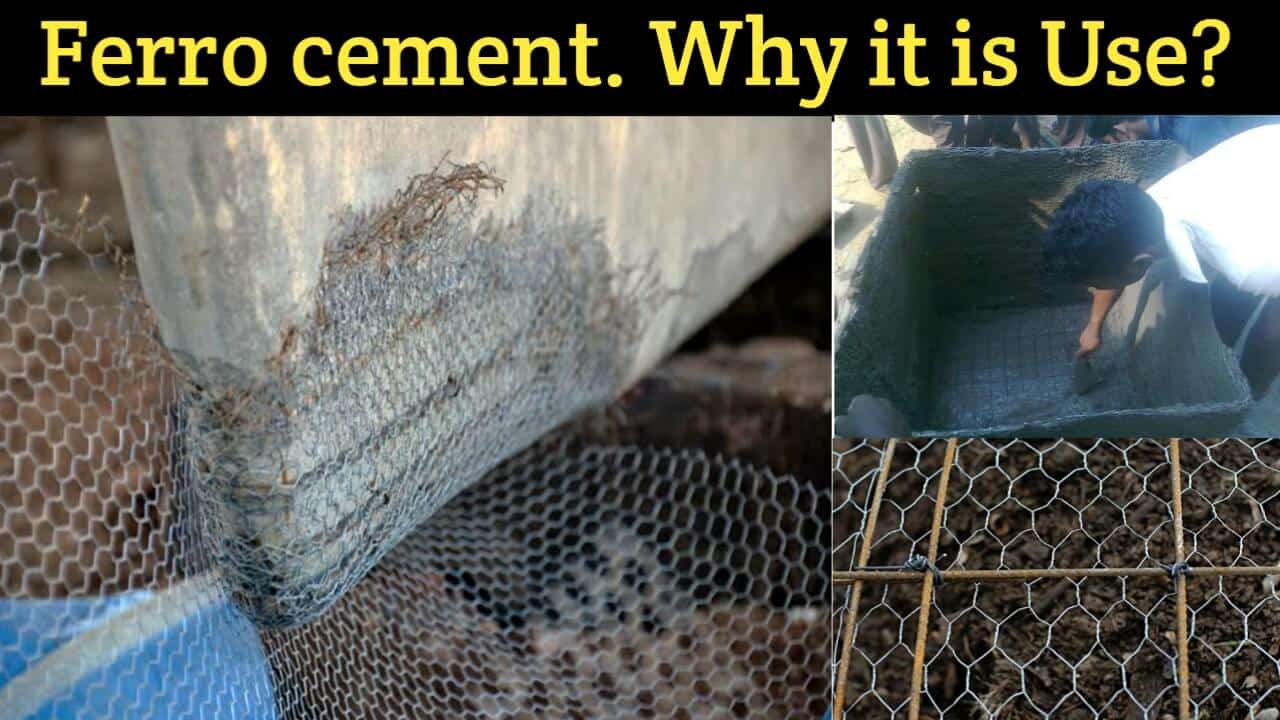

Ferrocement is a thin reinforced concrete structure in which the cement mortar mix is reinforced with a small diameter wire mesh.

Ferro Cement increase tensile strength and ductility of concrete due to use of small diameter wire mesh. Thus, concrete tensile strength, resistance against cracks, toughness, im-permeability, fatigue resistance increases.

Generally ferro means iron and cement is a construction bonding material.

The use of fibers in britle materials has been known for years. In the old days, carts used with bamboo strips in the mud walls and grass fibers in the mud on the walls.

Often, a Steel skeleton is also kept with the wire mesh. Which Holds the wire mesh in its position and increases the tensile Strength of Concrete.

Table of Contents

Who invented Ferrocement?

Frenchmen Joseph Monier The inventors of ferro-cement who dubbed it “ciment armé” (armored cement) and Joseph-Louis Lambot who constructed a boat with the system in 1848.

Lambot Exhibit this material universally in 1855 and give its name ferciment

Also Read: 12 Different types of stone masonry used in construction

How to Make ferrocement?

Ferro Cement is made by various material which are explain below.

Material Used in Ferro cement.

- Cement Mortar Mix

- Reinforcement

1) Cement mortar mix:-

Ferro Cement Composites have 95% Cement Mortar Mix and 5% Wire mess and Skelton Reinforcement.

The thickness of the section is 10 to 60 mm.

Fine aggregate(sand) used in ferrocement, according to grading zone II or III wise and maximum size of 2.36 mm and 1.18 mm. Sand smaller than 150 microns should not be used in Ferrocement.

Plasticizers or admixtures are also used to improve Workability, durability, Impermeability, water proofing, of ferrocement.

In ferrocement, the Sand/Cement ratio kept 1.5 to 2.5 and Water/Cement ratio kept 0.35 to 0.60.

(2) Reinforcement:

Two types of reinforcement are used in ferrocement:

- Wire mesh

- Skeleton Steel

1. Wire mesh

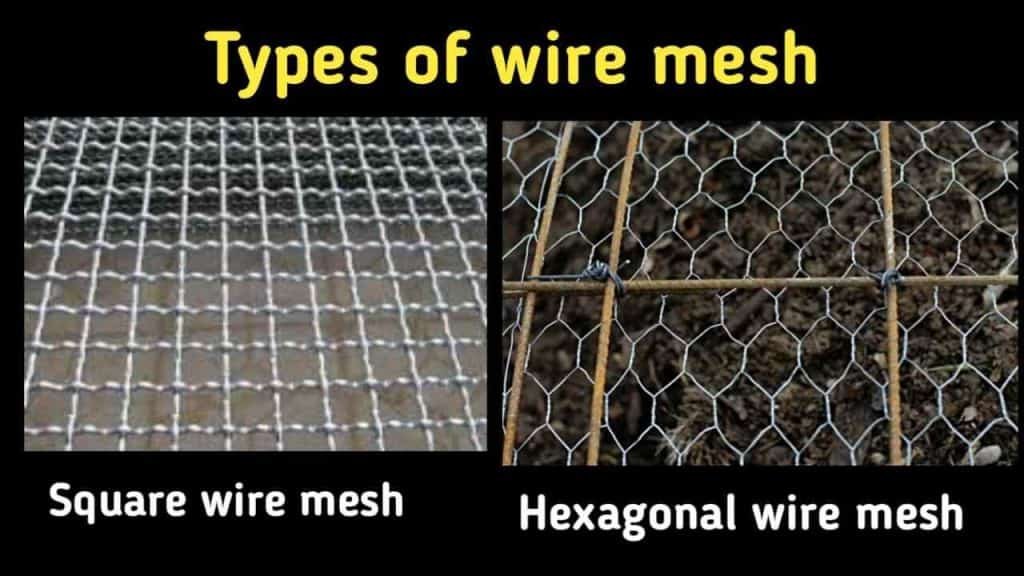

Wire mesh is made from 0.5 to 1.5 mm diameter galvanized wire, Kept 6 to 20 mm center to center by welding. Different types of wire mesh used in Ferrocement which is given below.

- Square woven wire mesh

- Square welded wire mesh

- Hexagonal wire mesh

- Expanded metal lath

The opening in a welded wire mesh is hexagonal or square. Wire mesh with hexagonal opening are also called chicken wire mesh.

Rectangle or square wire mesh are stronger than hexagonal wire mesh. Yield strength of square wire mesh 450 N/mm2 And the Yield strength of the hexagonal wire mesh is 310 N/mm2 to 410 N/mm2.

Also Read: 7 Best Methods of Dewatering

2. Skeleton steel:

Skeleton steel is made up of 3 to 8 mm diameter of Mild Steel Bars. The spacing of the rod is kept 70 to 100 mm.

Skeleton Steel Frame kept as per structure size.

Methods of Ferro Cement Construction:

Ferro Cement is constructed in four stages.

- Fabrication of skeleton frame

- Fixing of bars and mesh

- Application of Mortar

- Curing

The motor is applied by hand or shotcreting. Ferrocement does not use formwork in construction, so it is useful for curved surfaces like shells, etc.

Mortar impregnation is the most important stage. At the time of mortar impregnation, Hammering is done by using 100mm dia and 150mm long wooden tamping rod. Hammering with reinforcement is done with a wooden rod hammer.

When more than one wire mesh used, it should be kept 1 to 3 mm space between the two-wire mesh.

When the thickness of the member is more than 20 mm, use three layers of wire mesh and apply three layers of mortar.

The first mesh should be cured with mortar for 3 days. Then motor should be applied to the outer two layers.

Also Read: Importance of Timbering

Where ferro cement is extensively advantageous?

Ferrocement is extensively advantageous those which are explain below.

Application of ferrocement:

- Mobile homes

- Water light structures

- Silos and bins

- Boat bulls

- Biogas holders

- Pipes

- Folded plates

- Shell Roofs

- Kiosks

- Wind tunnel

- Swimming pool etc.

Why ferrocement is Used?

Various advantages of Ferrocement causing Ferro cement is widely used in Above sector.

Advantages of Ferro Cement:

- The thickness and weight of the Ferrocement structure is less so that the weight of the structure is reduced and due to reduced weight of the structure, foundation cost is also reduced.

- Ferrocement is more suitable for pre-cast units.

- No formwork required.

- The construction method is simple and does not require skilled labor.

- The repair can be done easily.

Properties of Ferro Cement:

- Thickness – 10 mm to 60 mm

- Steel – 5 to 8%

- Steel cover – 1.5 mm to 5 mm

- Ultimate tensile strength – 34.5 N/mm2

- Allowable tensile strength – 10.0 N/mm2

- Compressive strength – 27.5 to 60 N/mm2

Also Read: What is Polymer Concrete and sulphur infiltrated Concrete

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.