This article consists of a full descriptive article on sheet piles, its types, Uses, Construction Procedure, and comparison of different types of sheet piles.

If you get any valuable information from this article then please share it with your friends and follow us on different platforms to get updated with our latest article. Lets Starts

Table of Contents

What is Sheet Piles

Sheet piles are the vertical permanent or temporary retaining structure which is used to protect the construction of foundation and other structures from surrounding obstacles such as water or earth.

It is used for retaining walls, land reclamation, underground structures such as car parks and basements, in marine locations for riverbank protection, seawalls, cofferdams, etc.

Sheet piles are made of concrete, timber, steel or polyvinyl material in different shapes. It is installed in ground in sequence by using a hydraulic or vibratory hammer to create a retaining or protection wall.

Sheet pile is one of the best temporary retaining wall due to its different advantages as mentioned below.

Advantages of sheet piles

- It is reusable

- Availability of a wide range of sections, size and length

- Easy to construct

- Construction can be done desire shape

- Less & easy maintenance

- Easy to handle and lift due to its light in weight

- Less space required for construction

- Easy to adjust the length of pile

- Water-tight structure, best for cofferdam

- Good durability

- Economical

Also Read: What is Under reamed piles | Design Parameters

Different Types of Sheet Piles

Different types of sheet piles are classified based on shape, material, and structural scheme.

Types of sheet piles based on Shapes:

- U-Type Sheet Pile

- Z-Type Sheet Pile

- Hat Shapes Sheet Pile

- Flat web Sheet Pile

U-Type Sheet Pile

U-Type section is one of the most common type of steel section for sheet piling purposes. It can be used for both temporary or permanent type structure.

It is widely accepted by most designers for sheet piles design. It is best suitable for repeated use of works.

U-Types sheet piles have section modulus ranges from 874cm3/m to 3820cm3/m

Z-Types Sheet Pile

Z-types section is also one of the best alternative options for sheet piling. Z-type sheet piles provide a solid web connecting two flanges.

It is used for retaining and floodwall applications. However, where interlocking strength is required like filled cells, in such requirement Z-Type sheet piling is not used

Z-Type Sheet pile have section modulus ranging from 450 cm3/m to 4565 cm3/m.

Hat Shapes Sheet Pile

Hat Shapes Sheet pile is totally similar to U-type sheet piles but it has a large section and high range of sectional modulus.

Large flange width allows it to easily connect with other types of steel sections such as H-section to create good stiffness. Also, such a combination allows it to be used in wide applications.

Hat + H section sheet piles are used for River Revetment, Temporary Retaining Wall, Quay Wall, etc.

It offers superb drivability, high structural reliability and excellent cost-effectiveness.

Flat Web sheet Pile

This type of sheet pile offers great tensile strength. Flat web section is used to create large or circular wall protection system.

It is used for Quay Wall, Manmade Island seawalls, Cofferdam, and other types of structure.

Also Read: What is Diaphragm Wall | How to Construct Diaphragm Wall

Types of Sheet pile based on material

- Timber Sheet Pile

- Steel Sheet Pile

- Precast Concrete Sheet Pile

- Polyvinyl Sheet Pile

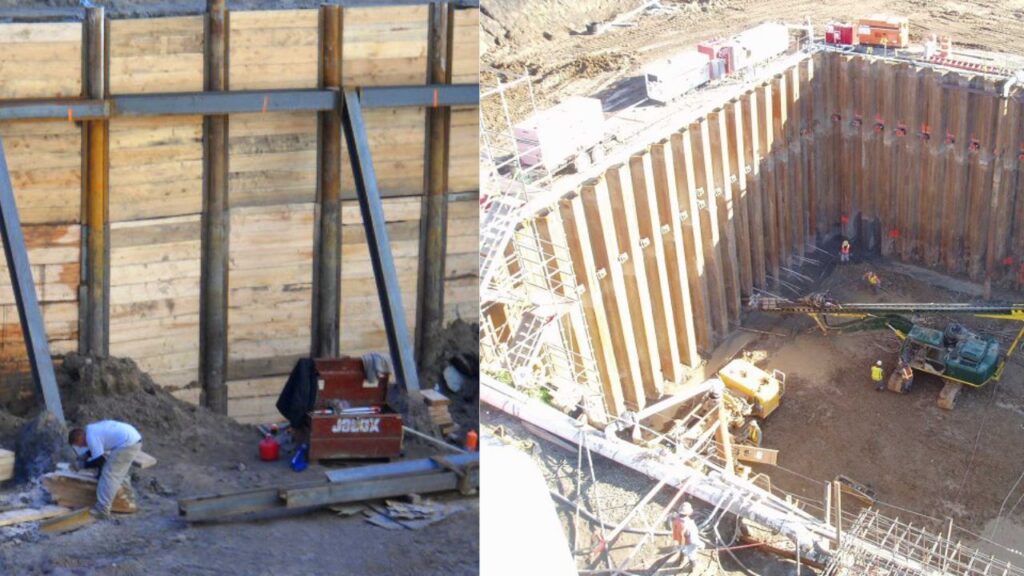

Timber Sheet Pile

Timber sheet pile was widely used a few time ago for the use of retaining wall in heavy engineering construction industry. But now a days it was not too much used for sheet pile purposes.

In few projects this type of sheet pile can be used for shallow excavation or temporary retaining walls.

Timber sheet piles typically consist of timber planks that are interconnected with a tongue and groove joint. When many timber planks are nailed or glued together to form a single timber sheet is known as Wakefield timber sheet pile.

However, timber sheet pile can be used for marine environment construction after well treatment.

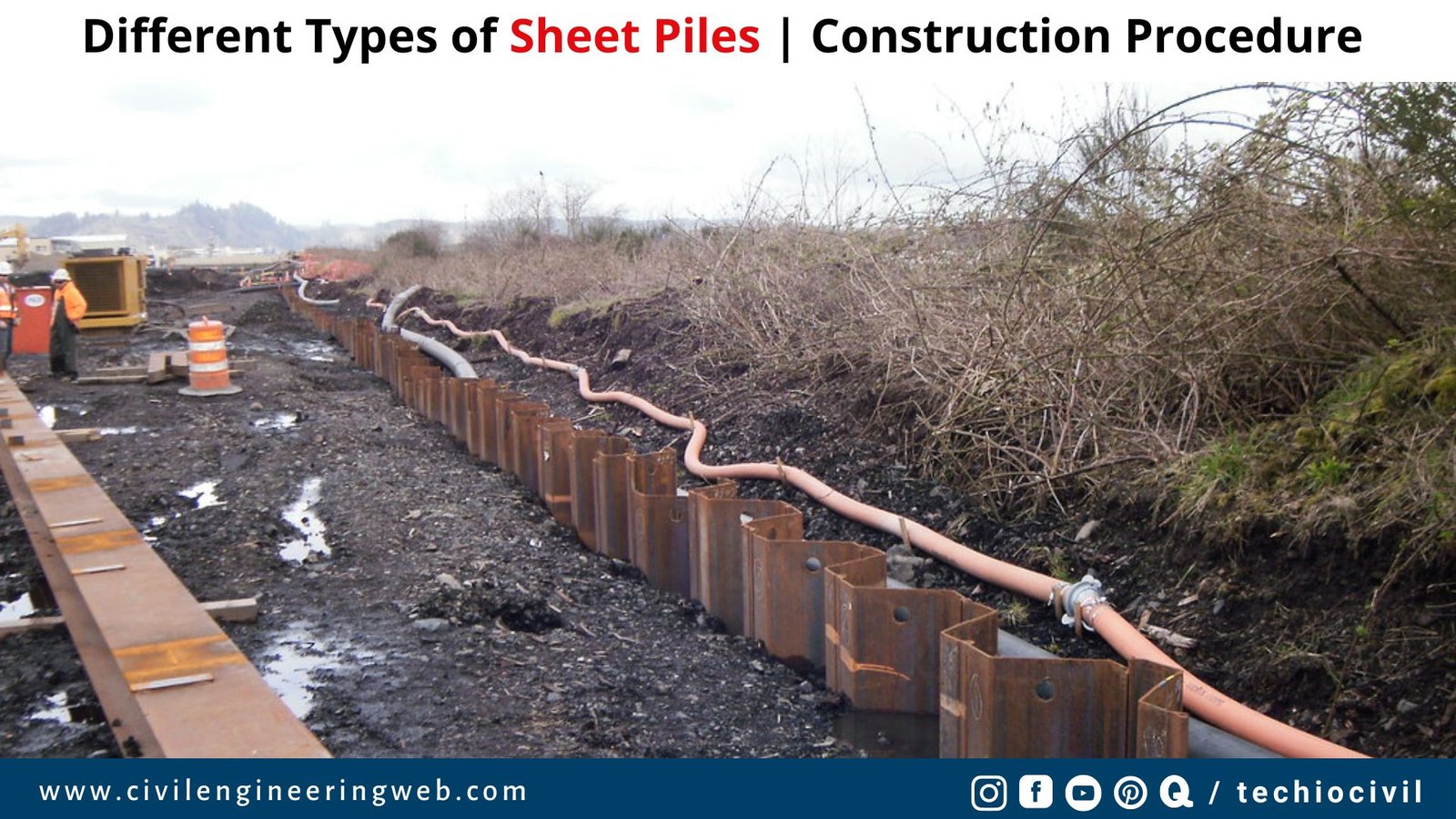

Steel Sheet Pile

Steel sheet piles are the most common types of sheet pile. It is widely used in every type of excavation.

Sheet pile is available in a wide range of sections such as Z-type, Hat Type, U-types & Flat web section which are already discussed in the above paragraph.

Sheet pile offers great strength as compared to all other type of sheet pile, however the strength of steel sheet pile can be increased by connecting section with other type of hot rolled section such as I-Beam section.

It offers great durability in any kind of environmental condition. Also the cost effectiveness of steel piles is much better than all other due to its easy to reuse, low maintenance, and low transportation cost.

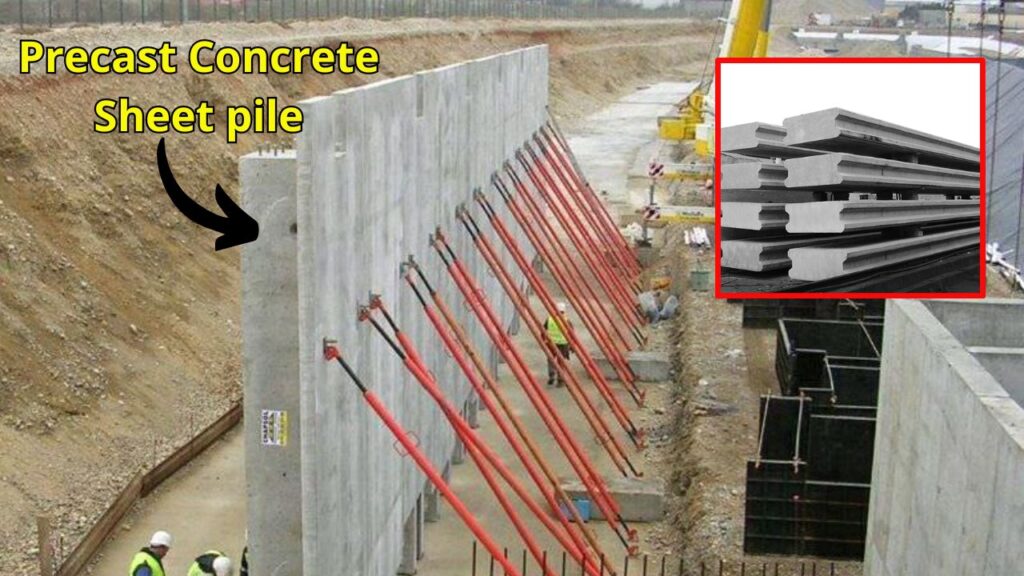

Precast Concrete Sheet Pile

This types of sheet piles are cast in controlled factory condition and then after it is installed on site. This is a type of concrete pile which is brittle in nature.

Mostly, this type of pile is not used for sheet piles purposes. However, where the steel or other type of sheet pile is not available or the environment is not suitable for steel section piles, in such cases precast concrete sheet piles are used for retaining purposes.

However, the transportation and hauling of precast concrete sheet piles is very difficult due to heavy weight and brittle in nature.

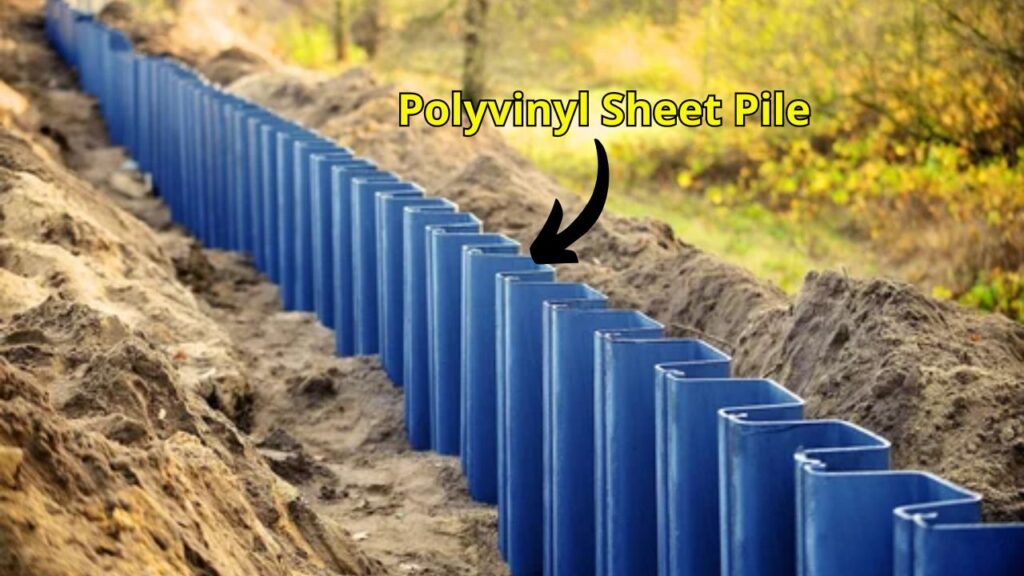

Polyvinyl Sheet Pile

Poly vinyl sheet piles are very similar to steel sheet pile the only difference is that it is fabricated by synthetic materials.

The Polyvinyl Sheet pile is an ideal option for shallow excavation or retaining works. It is widely used for erosion protection barrier or sea front projects.

Types of Sheet pile based on Structural Scheme

- Cantilever Sheet Pile

- Anchored Sheet Pile

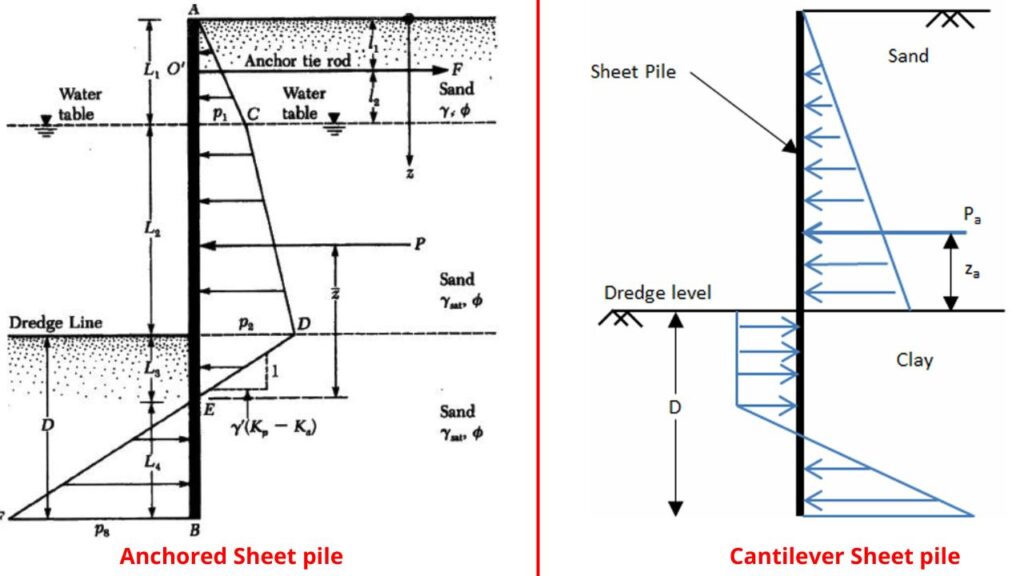

Cantilever Sheet Pile

This is a type of sheet pile based on its design action. Cantilever Sheet Piles are the piles which are supported at the bottom only. The bottom end of this pile acts as fixed by inserting the pile into enough depth in the ground.

The design of the cantilever sheet pile depends on the depth of excavation. In this type of pile, depth of the pile below the dredge level is much higher than the excavation height which is one of the disadvantage of this pile. It is suitable for shallow depth of excavation and retaining of earth.

Anchored Sheet Pile

The design of this pile is very similar to cantilever sheet pile, the only thing is different that the free end of sheet pile is anchored into soil by tie rod and concrete Deadman. It is widely used in excavation or construction of Onshore/Offshore structure. Such structural scheme of sheet pile allow to go for deep excavation by keeping less fixing depth into the ground below dredge level.

Construction Procedure of Sheet Pile

Construction procedure of sheet pile is very simple but the precautions during installation of pile is hard to inspect. However, here we explained the all important procedure of sheet piling with all safety and precaution measures.

Before installation of sheet pile, it is necessary to select appropriate driving and jetting equipment as per site condition. However, driving equipment is suggested by pile manufactures, while the jetting equipment shall have a minimum of two removable or fixed jets of the water or be a combination of air a water type.

After the selection of sheet pile and driving/jetting equipment, location of piling is marked on site as per drawings. After that sheet piles are placed on appropriate location. Also temporary Wales, templates or guide structure have to be carried out to ensure the perfect alignment of sheet pile.

After that, sheet piles are need to driving into the ground with proper size of hammering equipment and appropriate method to ensure no damage to the sheet pile. A protective cap shall be installed on the top of sheet pile to protect it during hammering procedure.

After the installation of sheet pile into the ground as per required depth, the pile cutting process has been carried out. The cutting of pile should be done in proper & neat manner for the safety purpose.

After the installation of first panel of sheet pile, second pile is connected with first one with proper connecting arrangement. and, then same procedure is followed to install the second panel of sheet pile.