Autoclaved aerated concrete blocks are the new sustainable materials that have lots of advantages and disadvantages in the construction industry. AAC blocks are mostly used in high-rise buildings to reduce the dead load of buildings and increase the insulation of buildings.

Recently, It was widely used in various sectors of construction industry. The main advantage of AAC block as compared to brick is its price. AAC Blocks are too cheaper as compared to Bricks and also give enough strength.

So in this article, we explain the all details of Autoclaved Aerated Concrete such as material, process, merit and demerits, sizes, applications, uses and so more.

Please read the article till the end and if you get any value from this article please share with your friends.

Table of Contents

What is Autoclaved Aerated Concrete?

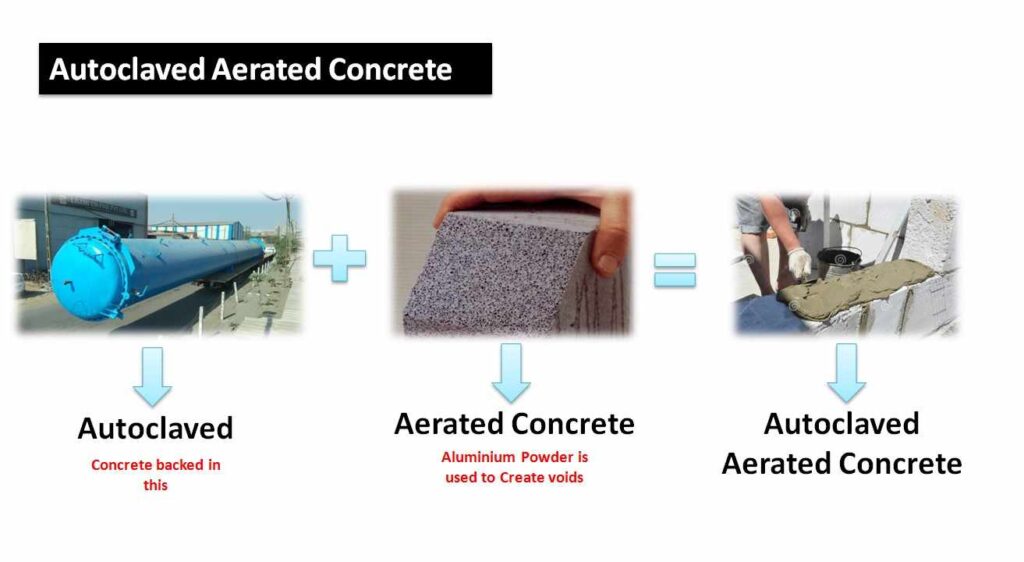

Autoclaved aerated concrete is an eco-friendly building material that is made by natural raw materials such as sand, fly ash, cement, lime, gypsum and aluminium powder.

Autoclaved aerated concrete is precast lightweight material that has more fire resistance and better thermal insulation.

The concrete has 70 to 80% air which is developed by aluminum powder. And the concrete is baked in Autoclaved which is one type of furnace. And that is the reason why it is called Autoclaved Aerated Concrete.

Autoclaved aerated concrete is also known as foamed concrete, autoclaved cellular concrete, autoclaved lightweight concrete, cellular concrete, porous concrete, etc.

It density is less as compared to bricks due to the presence of more air voids. These AAC block’s density varies from lighter to dense blocks.

- Lighter AAC Blocks: 450 kg/m3 to 750 kg/m3

- Medium AAC Blocks: 1300 kg/m3 to 1500 kg/m3

- Dense AAC Block: 2300 kg/m3 to 2500 kg/m3

Autoclaved aerated concrete blocks are mostly used as concrete masonry units. It was also used for an insulating property like in cavity wall, AAC blocks are used to construct inner leaf.

How to make Autoclaved aerated concrete?

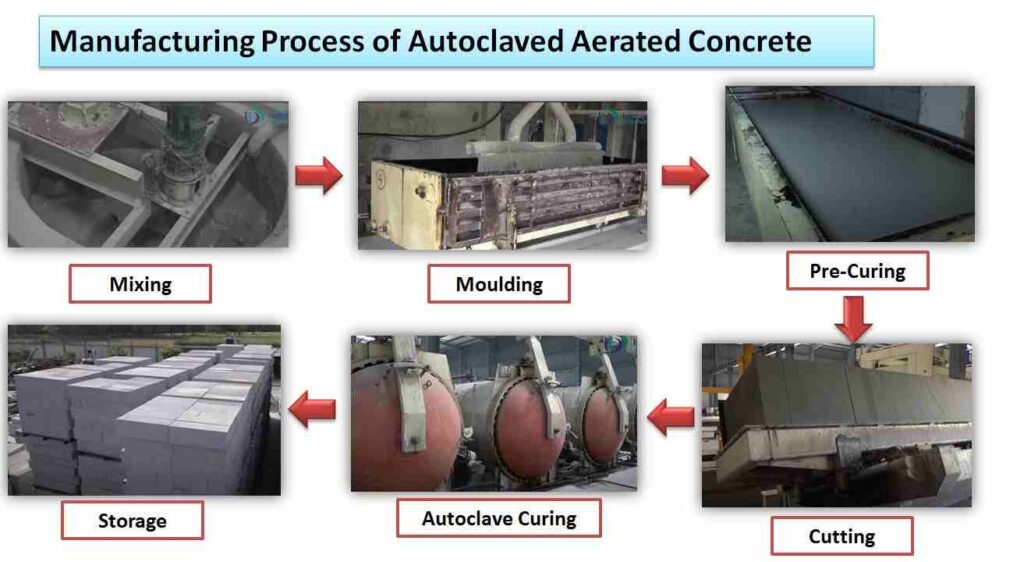

The manufacturing process of autoclave aerated concrete is very simple. Its includes the following stages.

- Mixing

- Moulding

- Pre-curing

- Cutting

- Autoclave curing

- Storage

1. Mixing

The tested ingredient of AAC such as fly ash, cement, lime, gypsum, sand, aluminum powder, etc. is mixed in appropriate proportion.

Note: The aerated concrete does not consist of any type of coarse aggregate. Aluminum Powder is used to create air voids in concrete.

2. Moulding

Moulding stage includes the laying of grease oil on every side of mould then filling of wet mix into the mould.

Note: The grease was lay on mould for easy removal.

3. Pre-curing

Pre-curing stage includes the setting of the wet mix. The filled mould was placed for 1 to 2 hours for the initial setting of concrete.

4. Cutting

In this stage, first, the thin layer of AAC blocks is scrapped at every side with the help of an automatic cutting machine. Then it was cut horizontally and vertically as per appropriates shape and size.

And the waste scrapped material of AAC blocks are reused in mixing of wet concrete.

5. Autoclave Curing

This stage includes the curing of AAC blocks, panels, etc. with the help of steam and pressure which helps to speed up the chemical reaction process.

First, AAC blocks, panels, etc are place into the autoclave machine with the help of crane. Then it was heated at 215 degrees Celsius temperature with the help of steam and pressure for up to 12 hours.

Then all blocks, panels, etc are removed from autoclave and placed for cooling.

6. Storage

After the cooling of AAC blocks, some samples of AAC blocks are sent for quality test and the remaining are stored on-site as per their shape and size.

And it was a full manufacturing procedure of AAC block. Let’s see the various sizes of AAC blocks.

Also Read: Traditional Concrete Production and Placement Process

AAC Blocks Sizes

Various Sizes of AAC blocks are available in the market. And the AAC block size also depends on location and suppliers. But majorly in India the 625mm x 200mm size AAC block used while the thickness varies as per type or mode of uses.

Also the AAC blocks are easy to cut and shape which provide more flexibility to use it in any construction.

Here, we listed the best suppliers of AAC block in india and various Size of AAC block as per suppliers.

| Magicrete | HIL Limited | JK Lakshmi Blox |

|---|---|---|

| 625mm x 250mm x300mm | 625mm x 200mm x 100mm | 600mm x 250mm x 100mm |

| 625mm x 200mm x190mm | 625mm x 200mm x 125mm | 600mm x 250mm x 125mm |

| 625mm x 200mm x 100mm | 625mm x 200mm x 150mm | 600mm x 250mm x 150mm |

| 625mm x 200mm x 125mm | 625mm x 200mm x 200mm | 600mm x 250mm x 200mm |

| 625mm x 200mm x 150mm | 625mm x 200mm x 225mm | 600mm x 250mm x 225mm |

| 625mm x 200mm x 200mm | 625mm x 250mm x 100mm | 625mm x 200mm x 100mm |

| 625mm x 250mm x 125mm | 625mm x 250mm x 125mm | |

| 625mm x 200mm x 225mm | 625mm x 250mm x 150mm | |

| 625mm x 250mm x 150mm | 625mm x 250mm x 200mm | |

| 625mm x 250mm x 200mm | 600mm x 250mm x 100mm | |

| 625mm x 250mm x 225mm | ||

| 625mm x 250mm x 100mm |

Best Suppliers of AAC Blocks in India

- JK Lakshmi Blox

- Hil Limited

- Magicrete

- Aerocon Blocks

- Siporex Block, etc.

Uses of AAC Blocks

The AAC blocks are used for various applications of construction industry.

- AAC blocks are mostly used as filler walls in framed structures.

- AAC blocks are used to construct the inner or outer leaf of the cavity wall that helps to increase the insulation of a building.

- AAC blocks are used in Roof/Slab that helps to reduce a dead load of the building which ultimately helps to the reduction of steel quantity in a structural member.

- AAC Panels are used for partition walls. Its fulfill all requirement of Partition wall such as lightweight, fireproof, ease in construction, easy to nail or screw, and a type of insulating material.

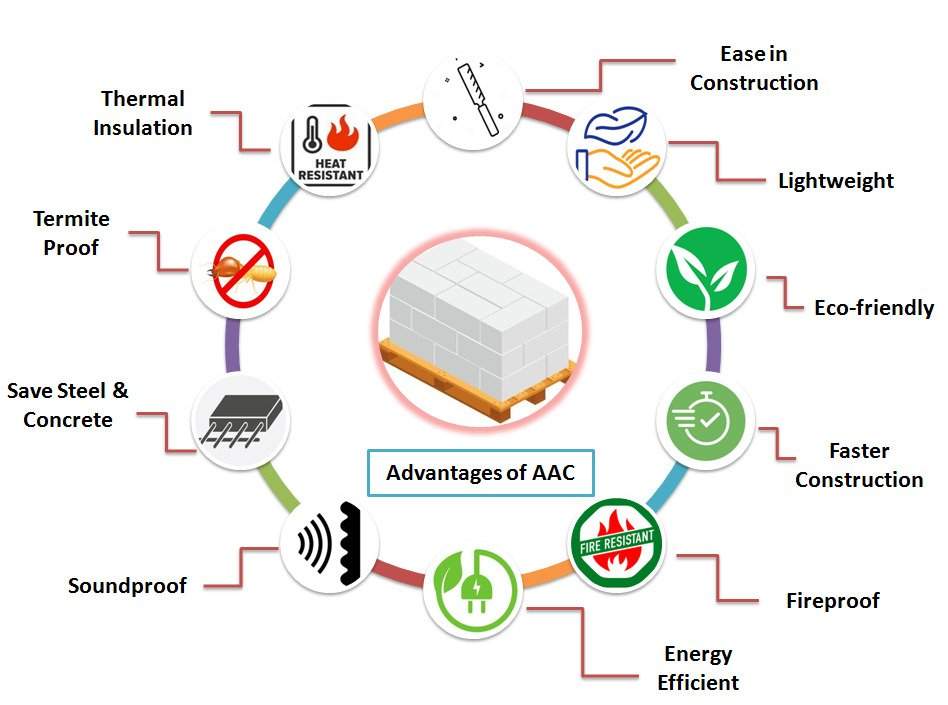

Autoclaved Aerated Concrete Advantages

The various advantages of AAC blocks are listed below.

- AAC blocks are lightweight materials that are helping to reduce a dead load of building.

- AAC blocks are Eco-friendly material.

- It was fireproof material.

- It can be cut and shape easily.

- Less tolerance as compared to other materials due to its precise and flat shape.

- It has high insulating properties such as sound insulation and thermal insulation.

- AAC blocks are termite-free.

- AAC block construction is faster as compared to other traditional construction.

- Enough strength to resist wear and tear.

- AAC blocks are the energy-efficient.

- It was available in a variety of forms and sizes.

- It was recyclable material.

- Easy to chase for electrical conduit.

- Reduce the quantity of reinforcement in structural elements due to lightweight.

- Less consumption of mortar in AAC construction.

Disadvantages of Autoclaved Aerated Concrete

The various disadvantages of AAC blocks are listed below.

- AAC blocks are not widely available.

- AAC blocks have lower strength as compared to concrete blocks or brick.

- It was Brittle material. It can be easily cracked if any type of additional load comes on it.

- Per unit cost of AAC block is high as compared to other material but for highrise construction, it was economical, due to less consumption of mortar.

- Exterior plaster (Stucco) or cladding is needed to protect it from weather effects or water absorption.

thanks for sharing this useful info on aac blocks. keep posting more.

Thank you Dear.