In this article, we explained what is shoring in construction, types of shoring, why shoring is required, in which condition shoring is used, full details of raking shoring, flying shoring, and dead shoring.

Table of Contents

What is Shoring in Construction?

Shoring in construction is the arrangement of wood or iron members used to support a wall. Simply it is a support system which is used to support walls etc.

In which condition shoring is required in a construction?

- Shoring is required when the buildings slender members shows sign of buckling or its should be defective.

- Shoring is required when the wall of the building shows signs of bulging due to bad workmanship.

- Shoring is required to repair cracks of the wall due to unequal settlement of the foundation.

- Shoring is required to support defective walls, roofs, compound walls, floors, etc.

- Shoring is required when the foundation is to be inserted into the deep ground.

- Shoring is required to make a large opening in the wall.

Types of Shoring

The types of shoring are as follows.

- Raking shores or Inclined shores

- Flying shores or Horizontal shores

- Dead shores or vertical shores

Also read: What is Formwork in Construction || 7 Types of Formwork Used

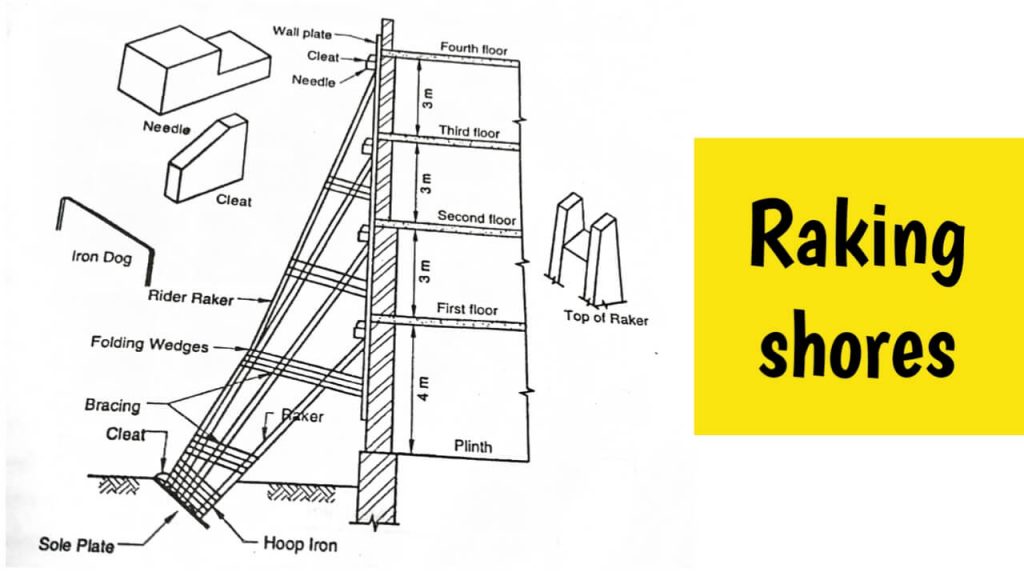

1. Raking shores or Inclined Shores:

In raking shores method, inclined member called rakers, are used to give lateral support to wall.

The raking shores consist following components that are given below.

- Wall Plate

- Needles

- Raker

- Cleats

- Rider raker

- Sole Plate

- Bracings

- Iron dog

Wallplate is attached to the wall by a needle. The needle is mounted 15 cm deep in the wall. The pressure is uniformly distributed over a wall due to the wall plate. The needle is strengthened with a cleat in order to do not get shared off due to the thrust of rakers.

The rakers are attached by a bracing. The bottom end of the raker is fastened to a sole plate tied with a bracing or hoop iron.

The following points need to be kept in mind during raking shoring in construction.

- The centerline of the racker and the wall should meet at floor level.

- The load on the racker shore cannot be accurately calculated, so the Factor of safety should be kept high in its design.

- The angle of the racker with the ground should be 45°. However, the racker can be adjusted at an angle of 45° to 70°. The angle of the top racker should not exceed 75°.

- The rider raker is used to reduce the length of the top racker.

- The length of the soleplate should be sufficient to accommodate the racker and the cleat.

2. Flying shores or Horizontal Shores:

Flying shores or horizontal shores are the arrangement of support system which is provides lateral support to two parallel walls when collapse or removal of the intermediate parts of building take place.

All types of shoring in construction, in which the shores do not reach the ground are the flying shores.

Flying shores have two types.

- Single flying shores

- Double flying shores

Single flying shores are provided when the distance between walls are less than or equal to 9m. If the distance is more than 9m, in this case double flying shores are provided.

Flying shores consists wall plate, needle, cleat, flying shore, strut, folding wedges, straining piece, etc.

The following points should be kept in mind for single flying shoring in construction.

- The centreline of the flying shores and struts and the centreline of the wall should meet at floor level. If the floor level is different on both sides then the framework should be designed properly.

- The load on the shore cannot be accurately calculated, so factors of safety should be kept high in its design.

- The angle of the strut with the horizontal shore should be 45° and it should not exceed 60° in any case.

- A single flying shore is used until the maximum distance between the two walls is 9.0 m. Double flying is used for distances from 9 to 12 m.

- A set of shoring supports two walls.

- This type of shoring does not cause any obstruction at ground level.

- When one building is taller than another building, the raking shore should be placed above the horizontal shore.

Also read: What is Timbering | Importance of Timbering | Timbering Methods

3. Dead Shores or Vertical Shores:

In this type of shoring system, horizontal members (needles) are placed on vertical members (dead shores). The needle is perpendicular to the wall, passing through a hole in the wall. The loads of the wall, roof, floor, etc., are transferred from needle to dead shores, dead shore to the soleplate.

Dad shore is used in the following situations.

- Dad shore is used when the lower part of the wall is defective.

- Dad shore is used when the foundation is to be inserted into the deep ground.

- Dad shore is used to rebuild the bottom of the wall.

- Dad shore is used to make a large opening in the wall.

In this type of shoring the needles (horizontal members) are placed at a distance of 1.5 m to 2.0 m. The floor should be properly supported from the inside. The Stress generated in different parts of the Dead Shore can be easily detected.

The following points should be kept in mind for dead shoring in construction.

- The load on the shore cannot be accurately calculated, so Factor of safety should be kept high in its design.

- Minimum three needles should be used for the openings.

- Horizontal members (needles) of the dead shores should be suitably braced.

- Shoring should be removed at least 7 days after new construction is completed.

- Building floor suitably supported from the inside of the room.

- In case of external wall week do not used dead shores, preferably used raking shoring system.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.