In this article, we Explained what is a caisson foundation, different types of caisson foundation, various construction methods of caisson foundations, pneumatic caisson foundation, use of caisson foundation, and so more in detail.

Table of Contents

What is a caisson foundation?

Caisson is defined as Structures that are poured into water or soil to remove water or semi-liquid material during foundation excavation and eventually become a permanent part of the underlying structure.

Caisson is used for excavation of river bridge foundations, pillars, abutments, or for protection of shore, for construction of push-ups, construction of lighthouses, etc. Caisson remains on the excavation site and eventually becomes part of the permanent construction.

Caisson is made of steel, R.C.C., wood, or embroidered iron. Wood is not used as it is relatively expensive and prone to fire. R.C.C caisson is heavy in weight, making it difficult to handle and float.

The cast iron caisson is suitable for open well caisson but not suitable for pneumatic caisson. The price of cast iron caisson, is higher compare to R.C.C. and steel caisson.

The steel caisson is considered to be the most suitable caisson. Steel caisson is usually made in double skin and the cavity between the skin is filled with plain concrete.

Uses of caissons foundation:

Uses or function of caissons foundation are as follows.

- To transfer the load coming on the pillars of bridges and buildings columns to the hardest level below the ground.

- If the caisson is placed close to each other, it acts as an impenetrable core wall for the earthen dam.

- To make way for deep shafts or tunnels.

- To erect enclosures for placing machines, pumps, etc. underwater.

- To protect the foundation from the lateral force.

Also Read: What is Cofferdam | Different Types of Cofferdam | Its Uses

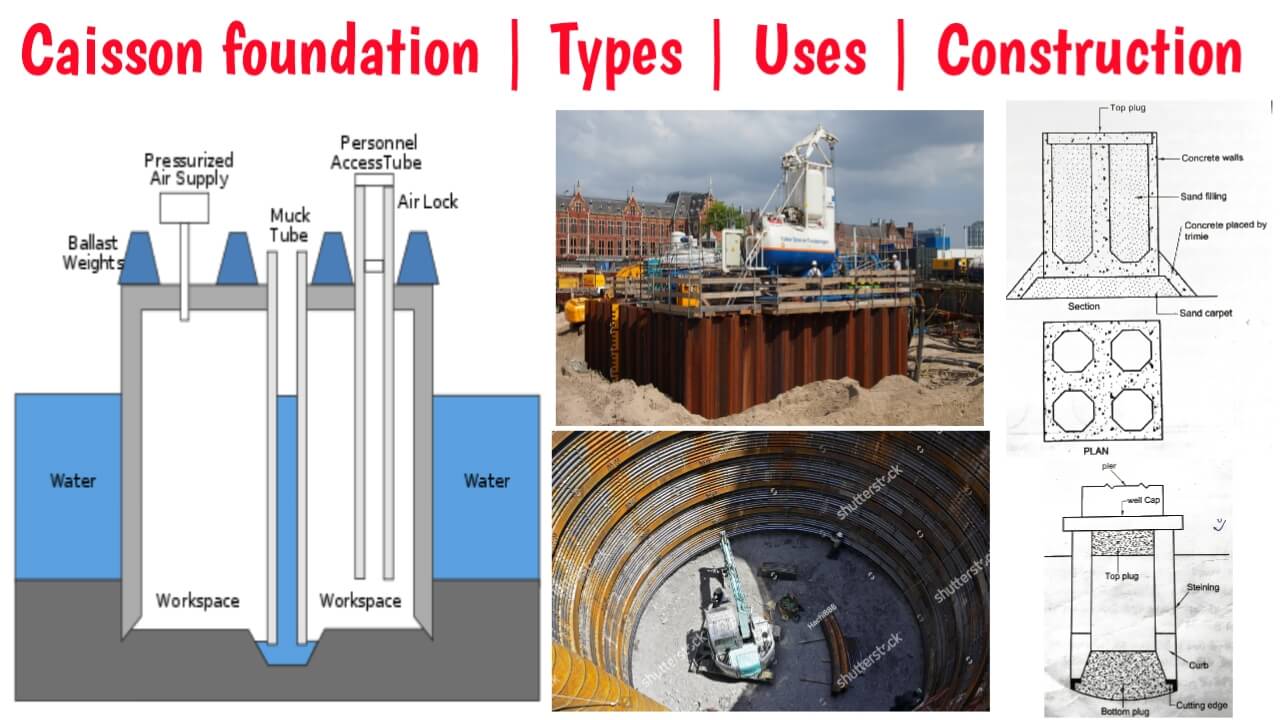

Types of caisson foundation:

The main types of caisson foundation are as follows.

- Box caisson (floating caisson)

- Open caissons

- Pneumatic caissons

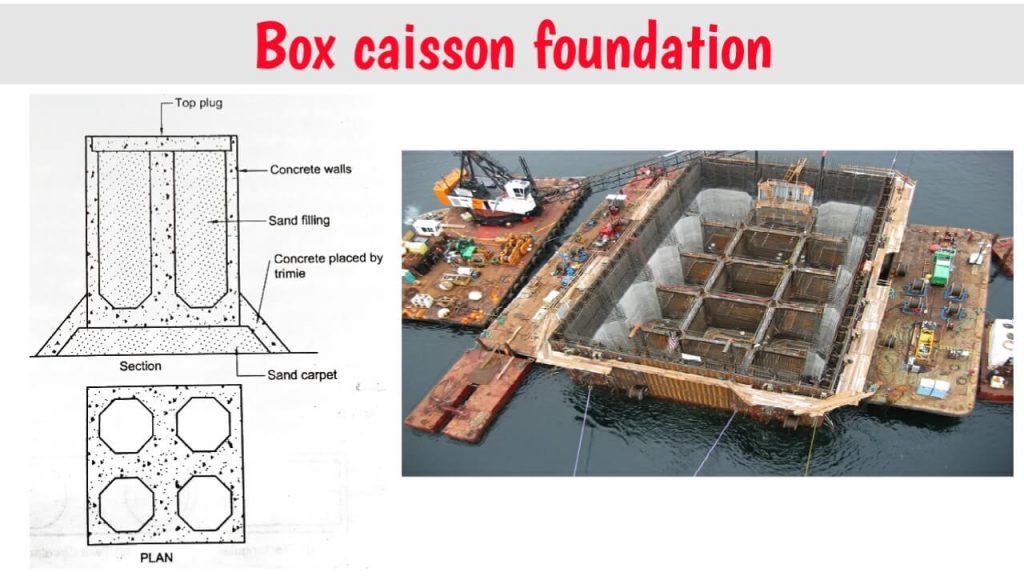

1. Box caissons (Floating caisson):

This type of caisson is open at the head and closed at the bottom. It is made of wood, reinforcement or steel.

Box caisson foundation construction method:

- The ground surface is leveled where the caisson is to be supported. If the caisson is to be supported on a group of piles, all the piles are made to the same height and a pile cap is made at the head. The caisson is usually supported on a sand carpet.

- The caisson is poured on the ground at the shore and cured on the ground itself.

- Then, the caisson is tied with a rope and pulled to sink in the right place.

- The inner space is filled with sand, gravel or concrete to immerse the caisson.

- The head of the caisson is sealed with concrete. Then the foundation is built on it. The bottom of the caisson is concreted with tremie pipe on all sides to keep the sand from the bottom bound.

Favorable conditions for construction of Box caisson foundation:

- When the base surface is already level.

- The velocity of water flow is slow.

- The depth of water is 6 to 8 m.

- The base material is loose so that it can be dug to create a flat holding surface.

Box caisson foundation is used where the hard layer is at a shallow depth and the water depth is shallow. Such caissons are used for fewer loads. This type of caisson is used for the construction of Quay walls, breakwater, etc.

Also Read: What is Tunnel Formwork System || Advantages || Process

2. Open caisson or well foundation:

Open caisson or well foundation is also called well. This type of caisson is exposed at the head and bottom. They are made of wood, steel, reinforced concrete or masonry. Such caissons are used as foundations of bridges and buildings.

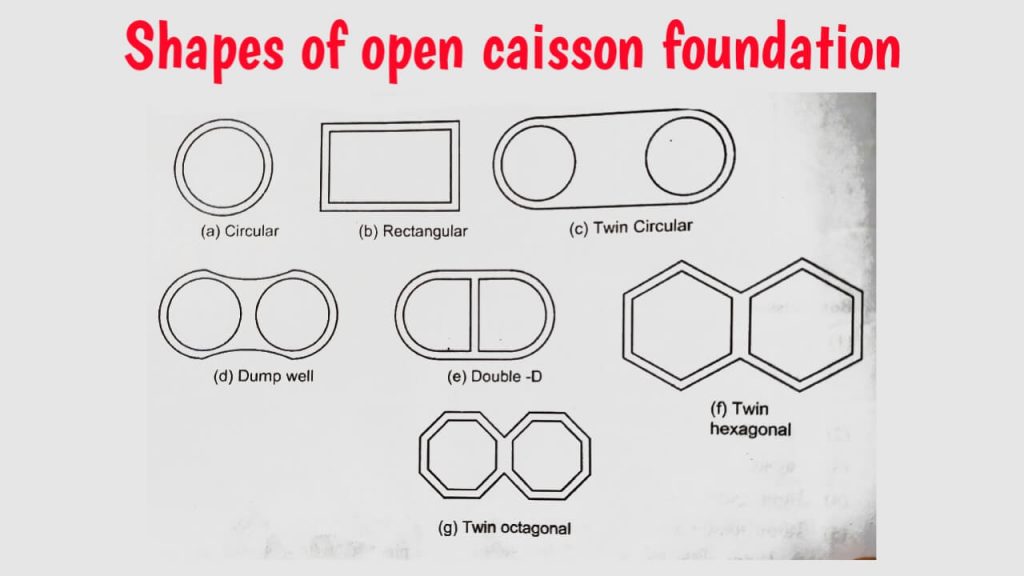

Open caissons come in different shapes. It has a cutting edge at the bottom. So that it is easy to sink the well.

The shape of the well is determined on the basis of the following.

- Type of Structure

- The vertical and horizontal forces acting on the well

- The lower part of the pier or abutment

- Cost of sinking

- The probability of tiling or shifting while descending the well.

The different shapes of the well caisson are given below:

- Circular caisson

- Rectangular caisson

- Twin circular

- Dump well

- Double-D

- Twin hexagonal

- Twin octagonal

The advantages of a circular well are as follows:

- Its perimeter is minimum, so the ratio of, sinking effort and skin friction required to maximum to sink the well. i.e. skin friction is minimized.

- Circular well sinking is uniform than all other shapes. And tilting or shifting is less.

- Since the diameter of a circular well is larger than the pier of a bridge, it creates more obstruction to the flow of water, so a double-D shaped well is more suitable for a larger pier, as it has less dredge area.

- Twin circular wells combine the advantages of both circular and double-D wells.

Also Read: What is Monolithic Construction Technology | Advantages

Types of open caisson foundation

Types of open caisson (well) are as follows:

- Single wells

- Multiple wells or monoliths

- Cylinders

i). Single wells:

This is a single walled open caisson. Such caisson is used where it is to be lowered to a shallow depth or where the caisson is to be lowered into the ground where the soil is loose.

Method of construction of single well foundation:

- The appropriate size and shape of the well is determined keeping in view the type and structural requirements of the super-structure.

- The soil is made dry by removing water from the area where the bracket is to be formed. Cofferdams, sheet piles, etc. are used to draw water.

- A well-sized and 3 to 4 m deep pit is dug at the place where the caisson is to be sunk. The cutting edge is then arranged at the bottom of the pit. The cutting edges are made of steel, concrete or wood.

- Masonry is constructed up to a slight height of the cutting edges.

- For R.C.C caisson Shuttering is done for pouring concrete by arranging reinforcement above the cutting edge.

- The concrete is then filled in for small lifts. After the filled concrete has gained sufficient strength, the caisson is started to sink.

- Removing the soil from the space inside the caisson causes the caisson to sink to the ground due to its own weight.

- As the caisson descends into the ground, the wall of the caisson becomes concreted.

- The caisson is lowered into the ground only after the new concrete is strong enough.

- The speed of lowering the caisson into the ground is slow due to the skin friction between the caisson wall and soil.

- Often the skin friction is so great that the caisson does not insert even after all the soil inside the caisson has been removed.

- In such a case the caisson is lowered to the ground by placing extra load like rails, sandbags, etc. on the caisson. Such bars are removed after the caisson is lowered into the ground.

- After the caisson descends to the required depth, a layer of 1.5 m to 4.5 m thick concrete is placed at its bottom, covering the bottom of the caisson.

- A bottom bucket or tremie pipe is used to do this concreting.

- After the concrete seals dry, water is pumped out from the well, and the empty space is filled with sand, gravel or concrete.

- A concrete plug is filled over the sand at the head of the well. Then R.C.C, a cap is casted. R.C.C. Pier is constructed on the cap.

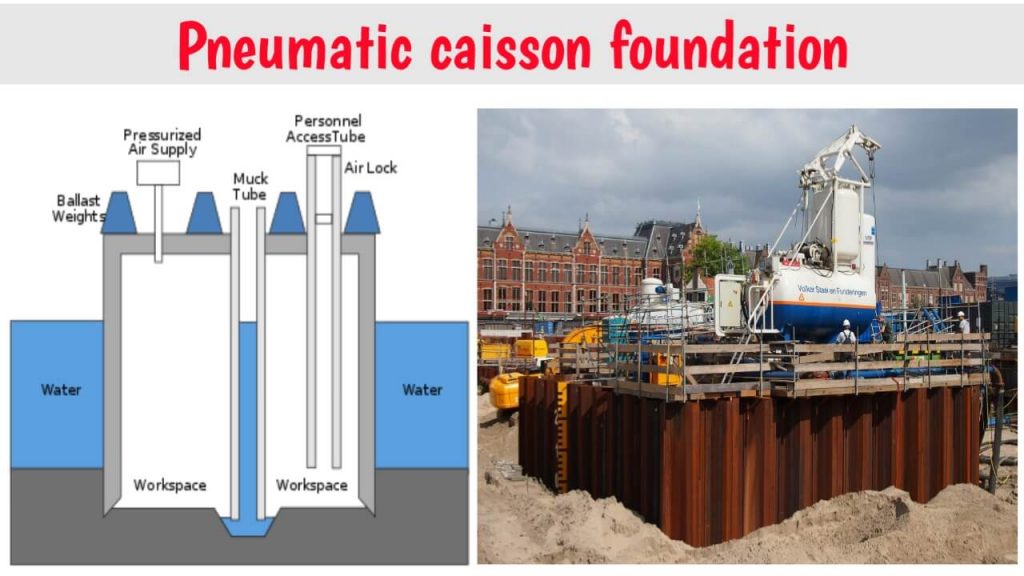

3. Pneumatic caissons foundation:

This type of caisson is closed at the head and open at the bottom. Some part of its bottom is free from external environment. This part is called the working chamber.

The working chamber is pressurized so that water or mud from the bottom cannot enter the caisson. That is, the air pressure in the working chamber is slightly higher than the water pressure at that surface.

Pneumatic caissons are useful when wells cannot be used as a foundation. Pneumatic caissons are especially useful where there are bowlders, pressed wood, masonry, etc. in the ground.

Method of construction of Pneumatic caissons foundation:

- Two shafts are generally kept in the caisson. One shaft is used for the movement of laborers and the other shaft is used to extract the excavated material.

- Often a third shaft is also used to lay the concrete to seal the bottom, each shaft has an airlock system at the head.

- Each airlock has two doors. One door opens into the atmosphere and the other door opens into the working chamber.

- When the artisan enters the airlock from the outside, the air pressure in the airlock is equal to the atmospheric pressure.

- Now by closing the door that opens into the atmosphere, the pressure in the airlock is gradually increased.

- When the air pressure in the airlock is equal to the pressure in the working chamber, the door to enter the chamber is opened and the laborer can reach the working chamber through a ladder placed in the shaft.

- The opposite process has to be done to get out from the working chamber.

- After adjusting the airlock, the water inside the caisson is pumped out and compressed air is turned on to prevent water or mud from entering the bottom.

- The laborers then proceed to dig the soil in the working chamber.

- The excavated material is pulled up from the airlock reserved for it. Thus the caisson is being dug deeper and deeper by digging slowly.

- When the caisson has inserted to the required depth, the bottom of the caisson is closed by the concrete bed.

- Adequate air pressure is maintained in the working chamber until the bottom concrete is properly dry.

- Subsequently, sand, gravel or cement concrete are sealed in the caisson by removing the airtight and other machinery from the caisson.

What is caisson foundation? types of caisson foundation pdf download.

Frequently Asked questions

Why caisson foundation is used?

Caisson is used for various purposes. some are listed below.

1. To remove water or semi-liquid material for the underwater foundation construction.

2. To transfer the load

3. To construct deep shafts or tunnels

4. for placing of machinery underwater

What is the difference between a caisson and a pile?

Pile is a type of deep foundation which is used to transfer load of super structure to ground soil. NOS of piles are used to construct single foundation.

While,

Caisson foundation is used to construct foundation in Underwater. Steel or other material Box inserted in underwater soil to act as water barrier. And then the Box is fill with concrete when foundation get its required depth.

What is the difference between cofferdam and caisson?

The basic difference is, Cofferdam is a Temporary Foundation where the Caisson is Permanent Foundation.

Also read:

- 7 Best methods of dewatering || procedure || necessity

- What is under reamed piles || construction procedure || advantages and disadvantages

- What is pile foundation || Types of pile foundation

- Shallow foundation | types of shallow foundation | uses

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.