Under reamed piles are one type of deep foundation. Under reamed piles are generally used in black cotton soil. Here we explain what is Under reamed pile foundation, the Advantages of under reamed pile, and disadvantages of under reamed pile, Types of under reamed piles, Construction procedures.

Table of Contents

What is Under reamed pile?

Under reamed piles are special types of piles manufactured by the Central Building Research Institute (C.B.R.I). Such piles are made of R.C.C. This type of pile specially design for expansion soil (Black cotton soil).

- The bottom end of the pile has a spherical enlarged portion called an under rim or bulb.

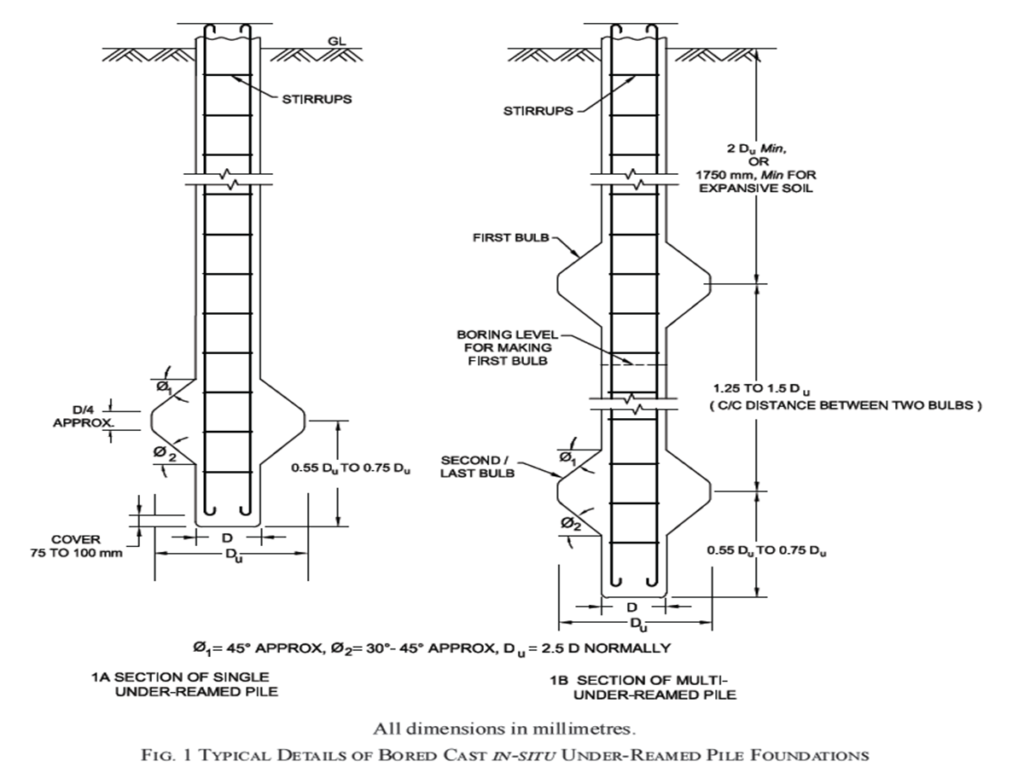

- The diameter of the pile is 20 cm to 50 cm and the diameter of the bulb is 2 to 3 times the diameter of the pile.

- Under reamed Pile lengths range from 3 m to 8 m.

- The spacing between the two piles is 2 m to 4 m.

- The safe load on the pile is 20 to 40 tons.

- The vertical spacing between two bulbs is 1.25 to 1.50 times the diameter of the bulb. More than one bulb is placed if the load on the pile is high.

IS Code for Under reamed piles:

Under reamed piles are used in which type of soils?

Under read piles foundation is used for the following soils.

1. Under reamed piles are generally used in black cotton soil:

This type of soil expands when it comes in contact with water and contraction occurs when water is removed. So that cracks appear in the construction done on such clay. An under reamed pile is used in the foundation to remove this defect.

2. Under reamed piles are used in low bearing capacity Outdated soil (filled soil)

3.Under reamed piles are used in sandy soil when water table is high.

4. Under reamed piles are used, Where lifting forces appear at the base of foundation.

Also read: What is Formwork in Construction || 7 Types of Formwork Used

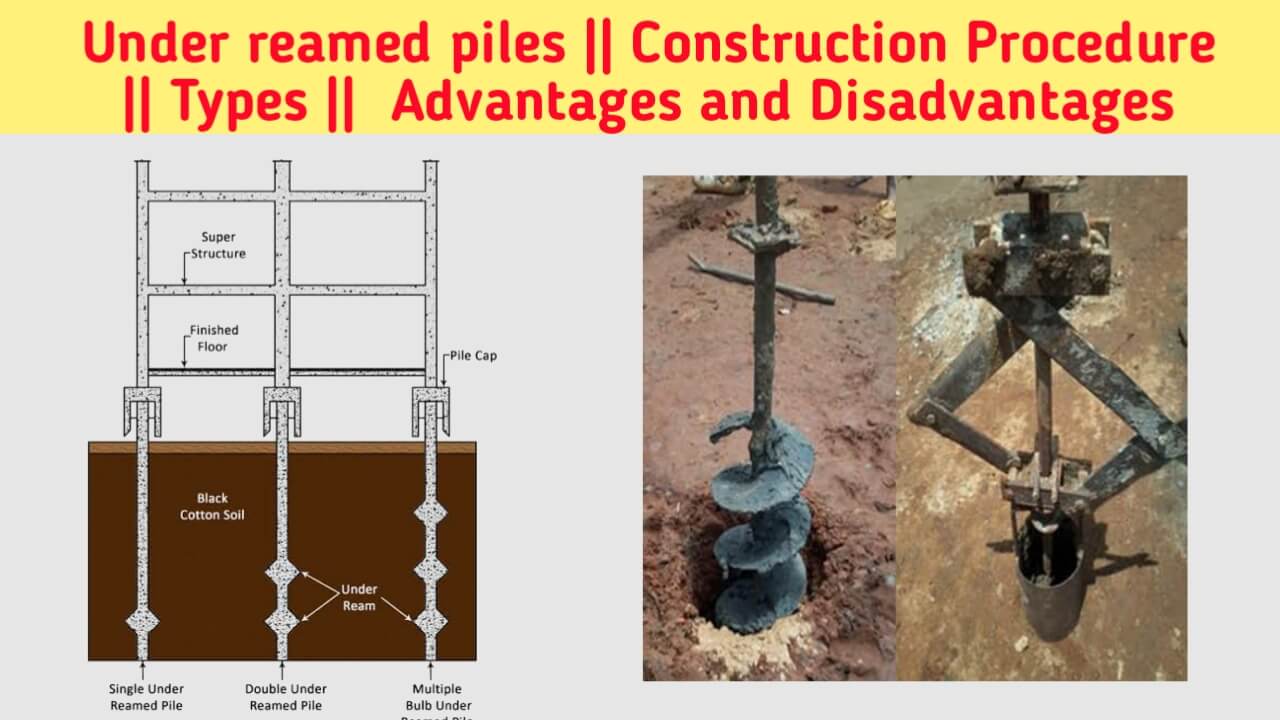

Types of Under reamed pile:

- Single-bulb cast-in-situ pile,

- Multiple-bulb pile.

A single bulb attached at the bottom end of a pile is called a single bulb under reamed pile. The pile with two bulbs is called a double bulb under reamed pile. And the pile with more than two bulbs is called a multiple bulb under reamed pile.

How to increase load bearing capacity of Under reamed pile?

The load carrying capacity of the under-read pile can be increased in the following ways.

- Increasing the number of bulbs

- Increasing the diameter of the bulb

- Increasing the length of pile

- By proper designing and placing of reinforcements in under reamed piles.

Also Read: How to construct foundation in Black Cotton Soil?

Construction procedure of under reamed piles :

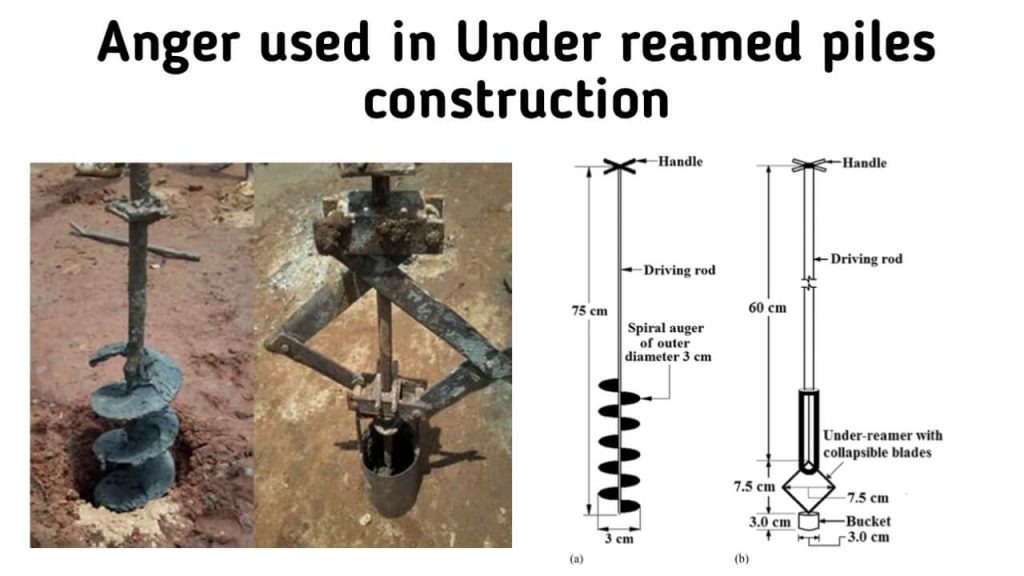

Under-reamed piles are mostly artificially constructed. Tool for Such piles of construction developed by C.B.R.T. Roorkee. This tool is fairly simple and light in weight. This tool has the following below.

- Spiral Auger

- Under – reamer

- Boring guide

A spiral auger is used to drill a hole in the ground for an Under reamed piles. Cutter is attached at the end of Auger to easily dig ground. Below the spiral auger, the filling bucket is hung to remove soil. Auger handles are also used to increase depth.

A special type of cutter is used to make the bulb, the diameter of the bulb can be increased by applying pressure on the handle of the auger.

Excavation is carried out from the auger only after passing the handle of the auger through a special design made on the head of a tricycle placed on the ground so that the digging of the pile hole is done in the vertical direction only.

After digging the pile hole and the bulb to the required depth, the auger is taken out and the Case of reinforcement is inserted in the hole. Then Concreting is done.

All the piles are connected to each other by forming a beam at the head of the pile. The wall is constructed over the beams.

Also Read: What is Geosynthetic | Types of Geosynthetics

Advantages and Disadvantages of under reamed pile:

Advantages of Under reamed Piles:

- Such piles are 15 to 20% cheaper than strip footing.

- Less material is required for such a pile.

- No heavy digging is required, so operations can be carried out even in the rainy season.

- There is no need for back filling in such piles.

- Shoring is not required.

- Dewatering is not required.

Disadvantages of Under reamed Piles:

- Required great workmanship.

- Skills required for placing of such type of piles.

- Maintaining verticality in ground is difficult. Because some time such pile are driven by hand-operated machine and it is very difficult.

- Required strict and regular supervision with great quality control.

Design Recommendation of Under Reamed Piles

The design of under reamed pile is based on is 2911 part-3 code of practice for design and construction of pile foundation part 3 – under reamed pile.

In case of under reamed pile, slump of concrete small range between 100mm to 150 mm for concreting in water free unlined borehole, for concreting by tremie, a slump of 150mm to 200mm shall be used.

In deep deposits of expansive soils the minimum length of piles irrespective of any other considerations, shall be 3.5m below ground level.

Minimum diameter of piles is 450mm, piles less than 600mm diameter is commonly known as small diameter piles while piles greater than 600mm dia are called as large diameter piles.

The diameter of Under reamed bulbs may vary from 2 to 3 times stem diameter. Normally 2.5 times diameter of stem is adopted.

For piles up to 30 cm diameter, the spacing of bulbs should not exceed 1.5 times the diameter of under reamed bulb.

The first under reamed bulb should be provided at minimum depth of 2 times the diameter of bulb.

In expensive soil it should also not be less than 1.75 m below ground level.

The minimum clearance below the underside of pile cap embedded in the ground and the bulb should be a minimum 1.5 times the bulb diameter.

The number of bulb in case of bored compaction pile should not exceed 25 in such strata.

The minimum diameter of stem for borehole needing stabilization by drilling mud should be 25cm.

The minimum diameter of stem for strata consisting of harmful constituents, such as sulfate, should be 30 cm.

The stem should be designed as a short column considering both concrete and steel by the limit state method or working stress method.

The minimum area of longitudinal reinforcement in stem should be 0.4%.

Minimum 3nos of 10mm dia or 3 nos of 8mm dia should be used. But generally 6 to 8nos 10mm dia bars are used.

The transverse reinforcement in piles should not be less than 6mm diameter mild steel bars at a spacing of not more than 30cm or stem diameter whichever is less.

The minimum clear cover over the longitudinal reinforcement shall be 40 mm.

Under Reamed Piles Pdf

Also Read :

- Shallow Foundation || Types of Shallow Foundation || Where Use

- 5 Method To Repair Brick Wall Defects || Repair of Brick Wall Cracks etc.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.