In this article, we explain various criteria of IS 13920-2016 For Beam that is kept in mind while ductile detailing of beam.

We include all criteria of ductile detailing which is influence the design parameters of beam. Also included shear reinforcements criteria as per IS 13920

In the case of ductile detailing of structure elements, we provide reinforcement as per earthquake force. Means the earthquake taken under consideration During ductile detailing of beam.

Table of Contents

Ductile detailing of Beams

Ductile detailing of beam includes the following criteria.

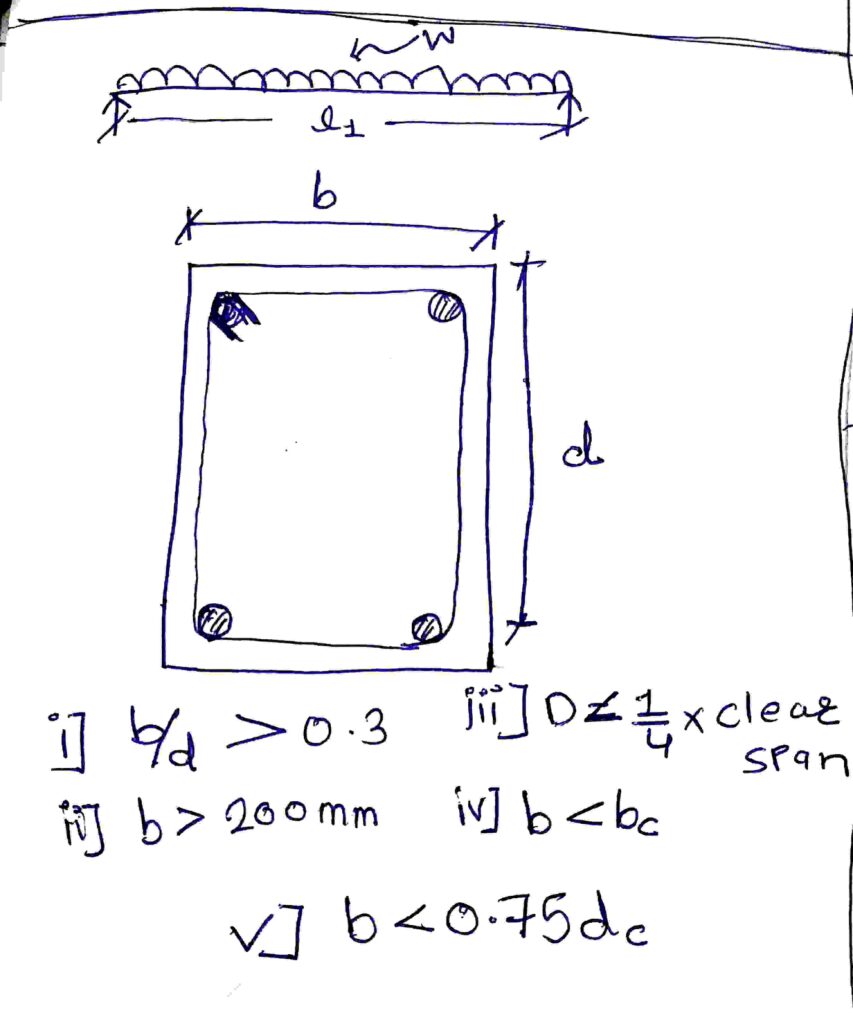

Size of beam

- The width to depth ratio of the beam should be more than 0.3

- The minimum width of beam is 200mm.

- The depth of beam should not be more than 1/4 of clear span. This may not apply to the floor beam of frame staging of elevated RC water tank.

- The width of the beam should not be more than the width of the supporting column + (0.75 x depth of column) or 2 times the width of supporting column, whichever is less .

Also Read: Ductile Detailing of Column as per IS 13920-2016

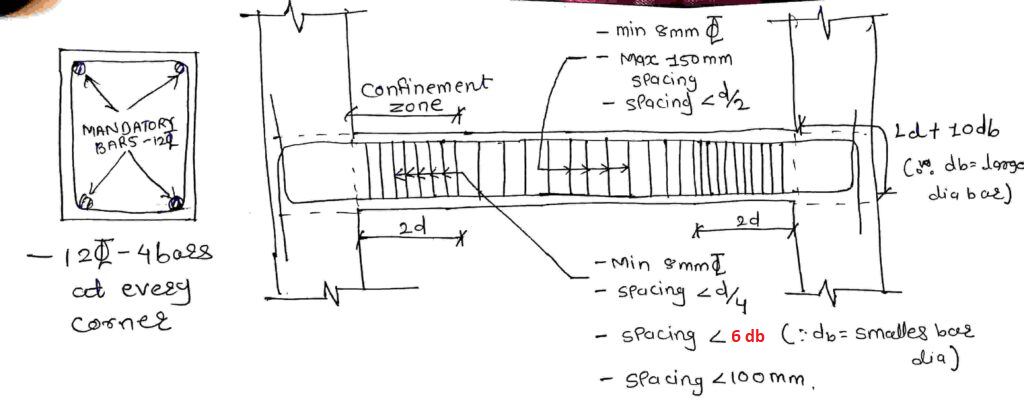

Longitudinal Reinforcement

Beam should have at least two 12mm dia bars on the top and bottom face. Means at least one 12 dia bar located on every corners of beam.

The minimum longitudinal steel ratio on any face at any section of beam is

Pmin = 0.24x √fck/fy

The maximum longitudinal steel ratio provided on any face at any section is 0.025.

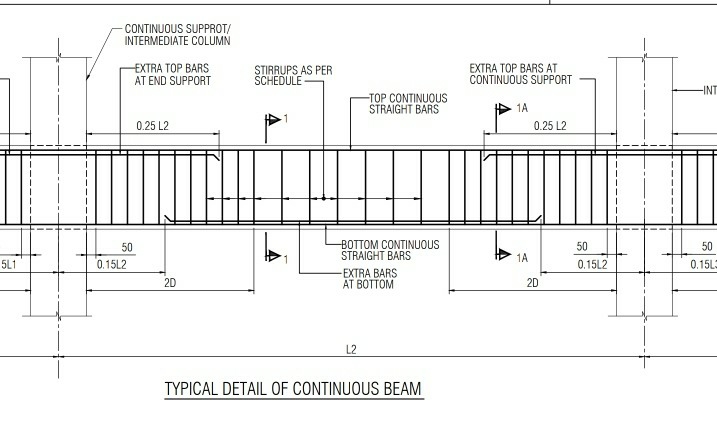

Longitudinal steel on bottom face of beam, at near the face of the column, shall be at least half the steel on its top face at the same section.

Longitudinal steel in beam at any section on top or bottom face shall be at least 1/4th of longitudinal steel provided at the top face of the beam at the face of the column. When the top longitudinal steel in the beam at the two supporting column faces is different, the larger of two shall be considered.

At an exterior, top and bottom bars of beams shall be provided with Anchorage length beyond the inner face of the column.

Anchorage length= Development length (Ld) + 10 times dia of bar – 90° bend allowance.

Also Read: What is Stub column

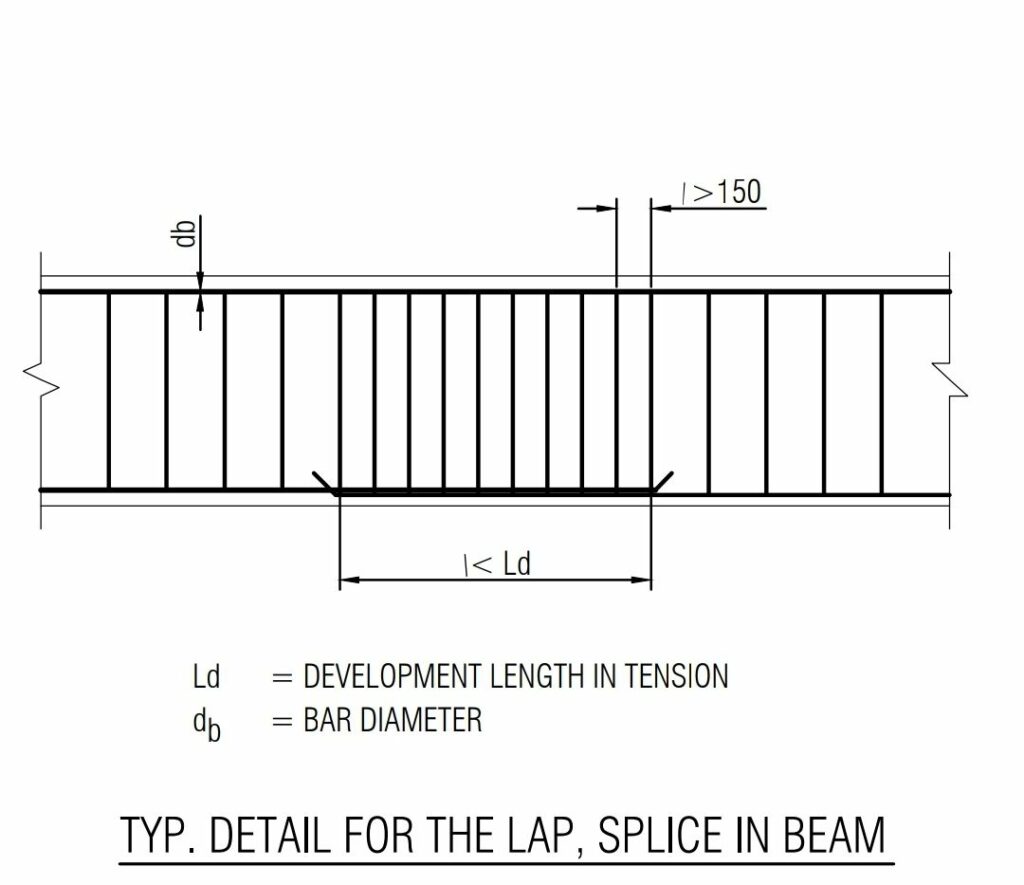

Splicing of Longitudinal Bars

In case of lap splices of longitudinal bars, the following criteria of IS 13920 should be kept in mind.

- The spacing of link over the splices shall not exceed 150mm.

- The Lap length should not be less than the development length of the largest longitudinal bars in tension.

- Lap splices should not provided within joint.

- Lap splices should not provided within a distance of 2d from face of the column.

- Lap splices should not provided within quarter length of beam adjoining the location where Flexural yielding may occur under earthquake effects.

- Not more than 50% area of steel bars on either top or bottom face shall be spliced at aany one section.

- Transverse reinforcements spacing over a lap splices provided should be as per closed spacing criteria.

Also Read: 4 best book for RCC Design

Transverse Reinforcements

As per IS 13920, Only Vertical links or stirrups shall be used in beams. Inclined links shall not be used. And the link hooks should be bent at 135°.

The minimum diameter of a link shall be 8mm.

Close Spacing of links

Spacing of link over a confinement zone ( 2d length) at either end of beam shall not exceed,

- d/4 (effective depth / 4)

- 6 times the diameter of the smallest longitudinal bar (main steel).

- 100mm.

Whichever is less, should be used as a spacing of Stirrups.

Closely spaced links shall be provided over a length of 2d at either end of beam. So over the remaining length of beam, vertical links spacing should not exceed d/2 of beam.

The first stirrup of beam provided within 50mm length from the face of column beam joint.

Also Read: Minimum & Maximum Percentage of Steel in Beam – IS 13920

Join Our Telegram Channel to get such type of information as soon as possible.

best

Thanks Dear

HELLO SIR!! LONGITUDINAL REINFORCEMENT FOR CONTINUOUS BEAM KA DIAGRAM JO APNE DIYA HAI WO IS 13920-2016 ME KAHI BHI NAHI HAI???? WHERE DID U TAKE THAT FROM??????? U CAN REPLY ME AT MY MAIL:- AKHTAR.FAHIM68@GMAIL.COM

What should be the maximum spacing of stirrups in beam as per IS 13920

300mm