In this article, we explained what is demolition, different types of demolition for building, demolition requirement, demolition plan, surveys for demolition, various method of demolition, implosion building demolition, pile hacking, factors affecting the selection of demolition, safety measures during demolition.

Table of Contents

What is Demolition?

Demolition means removing any building structure or part of it in a pre-planned and controlled manner.

Demolition is defined as destroying old buildings in a controlled manner when the design life of the building completed.

Definition of Demolition

Here two things is important for demolition. First Design life, Second is a destroying of old building in a controlled manner. Second thing is important for selection of demolition techniques.

This two things are a major factors which affect the demolition of building.

Demolition is done to ensure that the area around the building is not damaged or affected due to demolition.

Demolition Requirement:

Demolition is required in the following cases:

- When the building is very old.

- If any part of the building is weakened.

- If any internal changes are to be made in the building.

- When the design life of the building is completed.

- When the building has been severely damaged by an earthquake or other cause.

Also Read: 5 Best GPS Tracking Device for Construction Equipment

Survey for Demolition:

Detailed surveys and evaluations are required for the demolition of any building. The building survey includes the following:

1. Building Survey:

- Drawing records

- Material survey

- Hazardous material

- Photograph of the building, surrounding buildings

- The height of the building, distance from nearby buildings

- Type of building

2. Structural Survey:

- Drawing records

- Special structure

- Behavior of structure

- Structural support system

- Degree of deterioration

Demolition Plan:

For demolition approval, demolition plan is prepared on the basis of building survey. This plan is submitted to the local authority along with the application for demolition approval.

Demolition plan include the following parameters:

- Plan showing the location of the building

- Height of the building, structural system, the extent of damage

- Details of structures around the building, height, etc.

- Layout plan

- The proposed method of demolition

- Shopping and safety measures of surrounding buildings.

- Safety Measures

- Sequence of various steps of demolition work

- Plan for handling and disposal of debris

- Arrangements for site supervision, etc.

- Details of machinery to be used in demolition

Also Read: How to Construct Diaphragm Wall

Factors Affecting Selection of Demolition Method:

The following factors should be taken into consideration while choosing the method of demolition:

1. Type of demolition:

The method of demolition depends on the type of structure.

Demolition methods vary for different types of structure such as load bearing structure, RCC Framed structure, steel structure etc.

2. Size of the structure:

If the size of the structure is small, no special method is required for demolition. Hand demolition can be done. Special technique is required if the structure is large.

3. Duration:

Choose the method of demolition keeping in view the time frame available for the demolition.

4. Location of structure

5. Noise, dust, company limits

6. Available machines

7. Skills of labors

8. Safety

9. Surrounding Structures

10. Behavior of Structures, etc.

Also Read: Benefits of Google Earth for Civil Engineering

Types of Demolition Techniques in Construction

Types of demolition techniques used for building construction are given as in table.

| Non-Engineering Demolition | Engineering Demolition |

|---|---|

| Manual Demolition | Wrecking ball method |

| Pusher arm techniques | |

| Thermic lance techniques | |

| Non-Explosive demolition | |

| Concrete sawing method | |

| Deliberate collapse method | |

| Pressure jetting method | |

| Bursting | |

| Implosion technique |

1. Manual Demolition:

Manual demolition is also known as hand demolition.

This method of demolition is especially useful for breaking small structures in densely populated areas.

Manual Demolition of structures is done by laborers by hand.

Large machinery cannot go to the site as it is a crowded area.

To do this demolition method, use the following tools:

- Hammers

- Picks

- Wire cutters

- Welding cutters

- Hand driven hydraulic jacks, etc.

In this method of demolition, the demolition of the building is done from top to bottom.

Jack hammers are used to break concrete components such as beams, columns, slabs, etc. Oxy-acetylene torch is used to cut reinforcement steel.

A chute or skip is used to bring down debris from top floor to bottom.

If the distance of the edge of the nearest road from the building is more than 6 m (or half of the height of the building) then debris can be allowed to fall freely from the upper floor.

Sequence of manual demolition:

- Breaking the first cantilever parts.

- Remove water tank, lift cabin etc. from the roof before demolition of roof.

- Breaking the floor slab starting from the middle and moving towards the beam.

- The order of breaking the floor beam should be as follows.

- Cantilever Beam

- Secondary Beam

- Primary Beam

- Remove the non-load bearing wall before starting the demolition process.

- Break the load bearing wall and column after removing the beam from the top.

Also Read: What is Monolithic Construction Technology

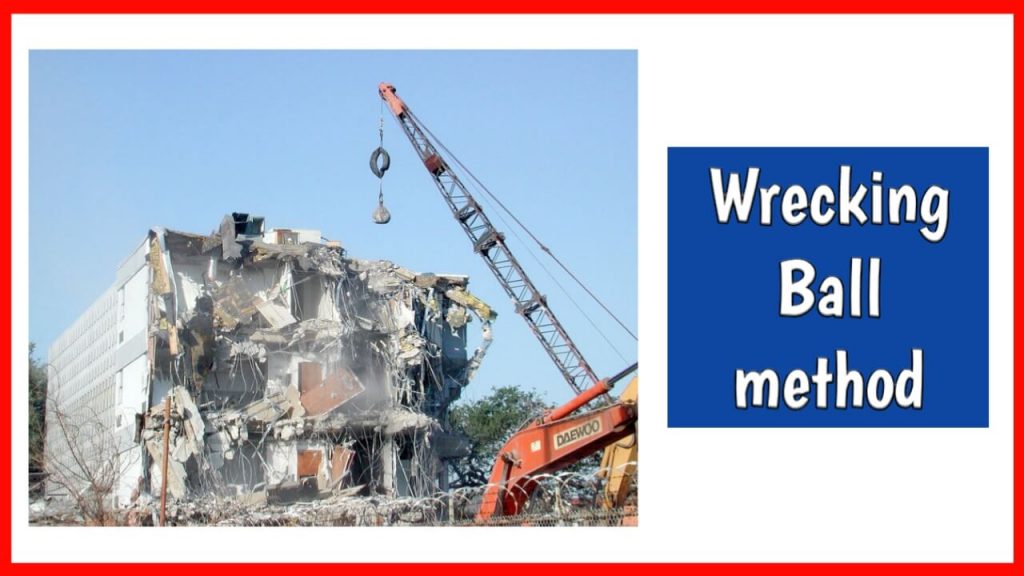

2. Wrecking Ball Method:

In this method of demolition, a steel ball weighing 0.5 to 2.0 tons is hung from a crawler mounted crane.

The impact of these steel balls breaks the concrete or machinery.

Two techniques are used in this method:

- Vertical drop of wrecking ball

- Swing action of wrecking ball

This method requires an experienced operator to handle the wrecking ball.

The building that is to be demolished must have open space for Crane movement around it.

If the building is to be demolished from the inside, the interior of the building must first be demolished to make the necessary space.

3. Pusher Arm Technique:

In this method of demolition, a machine like a “hydraulic excavator” is lifted with a steel pusher arm and pushed from the outside surface of the building.

In this way the machine should have a rigid base for operation from the ground. Also the distance from the building to the edge of the road should be at least 6.0 m,

If the buildings are connected to each other, the building to be demolished is separated from the adjacent building by hand demolition.

4. Thermic Lance Technique:

In this method of demolition, concrete and reinforcement steel are broken by melting at high temperature. In this way a temperature of 2000◦ to 4000◦ C is produced.

In pipes of aluminium alloy or iron alloy 14 to 18 mm diameter, wires of aluminium alloy or iron alloy are kept.

First, the metal lance is ignited by the flow of acetylene gas between the wires. Acetylene gas is converted to oxygen and the metal lance burns.

Causing the concrete and steel reinforcement to slowly melt and break.

“Powered lances” are often used instead of metal lances.

This way special measures need to be taken for safety.

This method is adopted only when other methods of demolition cannot be used.

5. Concrete Sawing Method:

This method of demolition is especially useful when the building is being demolished and repaired.

Useful where precision is required as well as control of noise, vibrations etc. are very necessary.

This method is useful when making opening in a slab or wall, braking concrete in the basement, service tunnel, flyover etc.

The following methods are used for saw cutting:

1. Wire saw cutting:

It uses diamond bit with loop wire saw. This method is suitable for foundation and mass concrete.

2. Diamond disc cutter:

This type of cutter is available in diameter of 1000 mm which is used for cutting concrete.

It was used for the demolition of a telegraph station building in Japan.

3. Diamond core boring machine:

Holes of 100 mm to 150 mm diameter can be drilled in concrete by using this machine.

Concrete can be easily cut by dealing close to the hole.

This method is useful in nuclear power plants.

Also Read: Precast Concrete Vs Site cast Concrete

6. Deliberate Collapse Method:

In this method of demolition, the key structural elements of the building are systematically removed or weakened so that the structure can be deliberately lowered.

This method is used only for the demolition of a building that is isolated from the surrounding building, plus the ground level should be almost level.

7. Pressure Jetting Method:

In this method of demolition, water jet is released from the nozzle at high pressure (250 – 300mPa) on the concrete surface. This jet cuts plain concrete due to abrasion.

An abrasive water jet is used to cut the RCC. In which garnet or steel particles cut the concrete.

This method has been developed for the demolition of nuclear power plants.

The rear area of the visual element that is to be broken by the water jet should be shielded so as not to damage individuals and property.

Water used in water jets should be recycled and reusable.

8. Bursting:

In this method of demolition, the building is dismantled by generating bursting force from outside on the building.

Two types of this method.

- Static bursting

- Dynamic bursting.

| Static Bursting | Dynamic Bursting |

|---|---|

| Burster with wedges | Water gun |

| Chemical Expansive Demolition agent | Gas cylinder |

| Cardox | |

| Mild explosives | |

| Explosives |

Burster with wedges:

In this method of demolition, bore holes are drill in concrete. In which mechanical wedges are inserted so that the concrete breaks due to expansion.

This method is used to break plain concrete and machinery.

Chemical expansive demolition agent:

In this method bore holes are drill in concrete. In this bore hole unslaked lime (chemical expansive agent) is ejected with water.

This mixture is expand due to hydration which breaks down the concrete.

Water gun:

In this method of demolition water is released in the bore hole at a pressure of 40 mPa. Concrete slitting occurs due to water pressure.

Gas cylinder:

In this method of demolition, flexible gas pipe with bore hole is fitted with rubber stopper which is attached to inorganic gas vessel.

Then opening the gas valve creates gas pressure in the bore hole and the concrete cracks.

Cardox:

In this method liquid carbon dioxide (CO2) is filled in a metallic tube and inserted into the borehole.

This tube is heated by an electric filament. So that it expands and spoils the concrete.

Mild explosives:

In this way holes are drill in the column. Dynamite is placed in this hall. Dynamite is arranged in such a way that the structure falls inwards.

9. Implosion Technique:

“Implosion” means an event where an external pressure is greater than the internal pressure when an object falls inwards. E.g., if air is pumped out of the glass tube, the tube will rupture.

Implosion is an advanced technique for demolishing high-rise buildings.

Demolition is done with this technique where the conditions on the site are not suitable for other methods of demolition.

This method is adopted when there are many buildings around. In this way the demolition of the building is done on its foot print.

The basic idea of implosion technology is quite simple, in which if the support of the building is removed from a certain point in front, the upper part of the billing falls on the lower part.

If the upper part is too heavy so, it collides with the lower part with sufficient force and causes great damage to the lower part.

In this method the explosives are arranged in such a way that the whole structure falls inwards towards its centre of gravity (c.g.).

Advantages of Implosion Technique:

- This technique is less expensive.

- Ground vibration do not occur.

- This method is fairly fast.

- This method is more suitable for demolition of high rise buildings, high piers etc.

Methodology used in implosion technique:

The various steps of demolition in implosion technology are as follows:

- Drilling of holes for placing explosives

- Quantity of explosive

- Type of explosives and detonators

- Test blast

- Wrapping holes

- Ballasting

- Falling of structure

1. Drilling of holes for placing explosives:

Holes of 25 mm to 30 mm diameter in columns, piers etc. are drilled at a distance of 200 to 300 mm centre to centre.

The hall is properly filled with explosive material.

2. Quantity of explosive:

The amount of explosive to be filled in the drill hole depends on the following:

- Size of the column

- Strength of the column

- How much demolition of the column is to be done.

In this way, especially the columns inside the building are completely destroyed, but the columns on the outside are not weakened so that the building collapses on the inside.

Also Read: What is Slurry Wall Construction

3. Type of explosives and detonators:

Two types of explosives are commonly used:

- RDX

- Gelatin

4. Test blast:

Test blast is done before actually blasting to determine the efficiency of explosives and detonators.

5. Wrapping of holes:

In this method, after filling the blast holes with explosive, the surface of the column is covered with gun bag, metal net or other suitable material. So that the debris does not fly into the air during the blasting.

6. Ballasting:

The process of ballasting of explosives should be done in a controlled manner so that there is a period of 1/100 seconds between two successive blasts.

7. Falling of structure:

The building collapses on its footprint so as not to damage the surrounding buildings or property.

What is Pile Hacking?

Pile hacking is new technique of demolition which is generally used for demolition of vertical structural member like columns of building, piles, piers, etc.

If we say, so it is a one special type of hydraulic jack method of demolition.

In pile hacking a mechanical equipment used such as the hydraulic breaker, John Deere excavators and air compressor etc.

Mechanical equipment used to break the bond between the concrete and the steel reinforcement bars.

The concrete is then chopped into small debris for removal.

Pile hacking is fastest method for demolition of vertical structural member such as columns, piles, piers.

Safety Measures During Demolition:

Disconnection of utilities:

- Before demolition of building, the following services should be separated:

- Electricity

- Gas Line

- Water Supply Line

- Drainage and sewage line

- If there is an underground route,

- most of the services (utilities) are underground. Properly survey and isolate.

General Safety:

- Placing danger signs around the demolition site.

- Place barricades at the entrance to the structure or set up watchmen

- Putting red lights at all barricades during the night.

- Provide safety equipment to each worker and explain its use properly.

- Provide celluloid lance Goggles to workers to prevent eyes against small particle, dust particle, concrete fragments, etc.

- Provide leather gloves to workers during Breaking of RCC Elements.

- Provide First Aid Box at demolition site.

- Provide fire extinguishers equipment at demolition site.

Also Read: Essential Construction Safety Measures and Equipment

Walkways and Sidewalks:

- To keep ‘walkways’ for the movement of workers.

- Keep free from debris or other broken materials.

- Before demolishing any building, temporarily close the road that is most affected for traffic.

- Remove children and other persons from the building.

- If the height of the structure is more than two storeys or 7.5 m, make a ‘sidewalk shed’ next to the structure.

Catch Platforms:

When breaking down the exterior walls of high-rise buildings, build a ‘catch platform’ of strong planks so as not to injure the lower level labourers or the general public on the ground.

Such catch platforms should not be more than 3 storeys below the floor wall which is breaking.

The width of such catch platform should not be less than 1.5 m. It should have a high parapet wall on the outside.

Protective Screens:

Prepare a bamboo scaffolding on the road side of the building to be demolished and put protective screen along with it so that no one is injured by blowing bricks, concrete, pieces of wood etc. during demolition.

Green Net can be used for such screens.

Temporary Supports:

Temporary support is required to withstand the load of machinery used during demolition, broken debris, large pieces of concrete falling from above.

Such temporary supports should be made of structural steel or heavy wood.

Surrounding buildings, public utilities, retaining walls etc. also need temporary support.

If there is a possibility of damage to the foundation of a nearby building, use methods like shoring, under pinning to support the foundation of such a building.

Dust and Noise:

- Continuous watering to prevent flying dust during demolition process.

- Install silencer with jack hammer and excavator to prevent noise pollution.

- The air compressor should be kind of super silence.

- Demolition work should not be done between 7 pm and 7 am.

Here is the best recommendation for you. One of the best books on Demolition of building is ‘Demolition: Practices, Technology, and Management’ by Richard Diven.

Types of demolition techniques for building structure video tutorial

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.