Dampness and efflorescence reducing the durability of the structure and give a negative impression as an appearance point of view. therefor in this web we explain how to repair dampness in the wall, how to fix efflorescence in wall, methods, techniques and so more.

Table of Contents

Repair of Walls from Dampness:

Damp proof coarse is provided over the plinth at 45 to 100cm above the ground level to protect wall from dampness. DPC is usually a layer of concrete, which is 40 to 50mm thicknesses in a 1:2:4 proportion.

In many buildings, beam is placed at Plinth level about 100mm thickness with steel rod. But in the old buildings where DPC is not placed, there are questions to easily moisture come in the walls.

Method to Fix Dampness in Wall:

- Creating a new Damp Proof Coarse(DPC) level.

- Injecting chemical in Plinth.

- Injecting Resin mortar with pressure.

1. Creating a new Damp Proof Coarse(DPC) level :

In this way, New DPC layer provided at a place of old DPC layer of building.

In this method mortar bed is removed by help of cutting above the two layer of brick from the ground level. This mortar bed is cut until the length of about 1meter at a time. The new DPC waterproofing compound is filled in this place.

This method is very slow. If the wall is poor, then the structure settlement and cracks are likely to occur in building. This way is not used specifically.

2. Injecting chemical in Plinth to repair dampness :

In this method the inclined hole is drill in the plinth portion of the wall. Injecting soluble silicon chemical with water in this hole. This causes a created watertight layer at the plinth level.

Silicone Paints are used for water-proofing of the outside wall. So rain water does not enter the wall.

Two method to feed chemical into the hole.

- Pressure Injection

- Gravity Feed

1. Pressure Injection:

- In this method, the plaster on the layer of 3 – 4 bricks above the ground level is removed.

- 12 mm diameter hole is done until the 2/3 depth of the wall thickness.

- The horizontal distance between such a hole is kept 150 mm.

- This hole is slipped out of the outside.

- Injecting polyurethane resin in this hole with the help of jel presser pump.

- Keep 0.3 to 0.7 MPa Pressure for a solvent-based solution and 0.1 to 0.3 MPa pressure for a water-based solution.

- Eventually, the hole is closed with a waterproof motor.

2. Gravity Feed:

- The simple Gravity Feed method is also used to make wall damp proof.

- In this method, inclined hole drilled in wall with 25 mm diameter, done until the 2/3 depth of the wall thickness.

- Rubber tube attached to this hole.

- The above end of the rubber tube container filled with a solution of soluble silicone.

- This solution is allowed to flow from the Gravity Force.

3. Injecting Resin mortar with pressure to repair dampness :

- In this method, 20 to 30 mm diameter inclined hole drilled in the 2/3 of the thickness of the wall.

- Such hole inclined at an angle of 20 degrees to 30 degrees in a downward direction with 30cm center to center distance.

- Special cement mortar (styrene-butadiene resin or epoxy resin) injecting in such type of hole with the help of chauking gun.

- This resin is dry and becomes hard which is make an impervious layer on it. That prevents moisture.

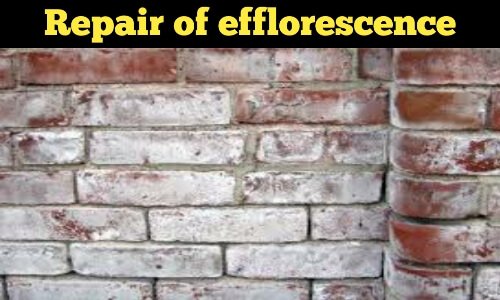

How to Fix Efflorescences in wall?

White crystal substance or salt powder come on the surface of the wall which is known as Efflorescence in the wall. If the salts are present in brick, sand, water and, other building material then absolutely Efflorescences occur in the wall.

Remedies to prevent Efflorescences in wall:

- Using salts free bricks, sand, water, and other building material.

- Providing DPC at a plinth Level of the wall.

Procedure to repair Efflorescences in wall

- To repair Efflorescences from the wall, the first step is to remove plaster from the wall.

- Then Wipe and Clean the brick surface with the help of a wire brush.

- Then after cleaning the brick surface by spreading low hydrochloric acid solution( solution ratio is 1:5 in which 1 indicate hydrochloric acid and 5 indicate water.)

- Then again wipe the brick surface by wet brush.

- Then construct a new plaster on brick surface and cured it for required days.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.