Table of Contents

TRANSPARENT CONCRETE

|

| Transparent concrete |

What is transparent concrete?

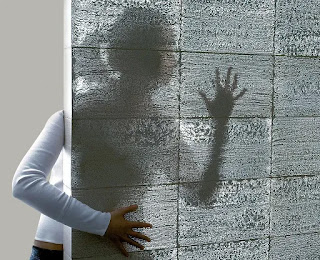

Transparent concrete is a hardened concrete which allows pass light through it. It is also known as light-transmitting concrete or translucent concrete.

Generally, the house is a basic requirement of people but in modern times people need the decorative and good aesthetic view of the house. Transparent concrete is the best example of decorative construction. Because the transparent or light-transmitting concrete is pass light through it. In a night the light-transmitting concrete is more decorative. This concrete is also used for another purpose.

Generally, transparent concrete is similar to ordinary concrete because the strength of both concrete is similar. But the major disadvantage is the transparent concrete is costly compare to ordinary concrete. Another detail is discussed below please read the full article.

Introduction: –

|

| TRANSPARENT CONCRETE |

Transparent concrete or light-transmitting concrete or translucent concrete is a smart construction material that allows pass light through it from one side to another side.

Due to some amount of coarse aggregate content of concrete is replace with light-transmitting material or optical fibers. In this concrete, the high amount of fine aggregate is used or fine material is used.

Transparent concrete is used to provide a better aesthetic view of a building or other architectural purposes.

Light transmitting concrete is also known as LiTraCon. The weight property of this concrete is light in weight compared to normal concrete. And also transmitted more light compare to normal concrete.

Transparent concrete or light-transmitting concrete is made by precast. It is available as prefabricated building blocks and panels. Transparent concrete is used in floors, pavement, celling, load-bearing walls, partition walls and other architectural purposes.

The main purpose of transparent concrete is the maximum used of sunlight and reduce the electric power consumption and using the optical fiber to sense the stress of structure.

History:-

|

| TRANSPARENT CONCRETE |

The Transparent Concrete Concept Is First Found In 1935 by Canadian patent. But due to the development of optical fiber and other materials, this concept is not more popular.

But after some time this concept also comes and in 2001 the idea of transparent concrete is found by Hungarian architect aron losonczi. In 2004, he started the german company, named LiTraCon, and started producing LiTraCon commercially.

Materials ;-

Cement:-

cement is a common and most important material for any concrete. Cement is a binder material that is used for a better bond between the aggregate and another material of concrete.

In transparent concrete the optical fiber is only responsible for transmission light from concrete, so no special type of cement is required. Ordinary portland cement is mostly used everywhere, therefore this cement is used for transparent concrete. Cement is available different grade like 33, 43, 53 and available at different prices.

Sand:-

the transparent concrete or light-transmitting concrete is manufactured by only fine material or fine aggregate, the size of sand should pass through 1.18mm sieve.

The fine material is free for impurities because this material is inert material means no take reaction. example alkali-aggregate reaction and etc.

Water;-

the water used for transparent concrete is drinkable quality water. Water is free from impurities. The water has clear and ph of water lies between 6.5 to 8.5.

Optical fiber;-

|

| OPTICAL FIBERS |

the optical fiber is the thin fiber of glass or plastic that transforms light from one point to another point. The study of the optical fiber principle is known as fiber optics. fiber optics is part of applied science and engineering.

The volume of optical fiber is 4 to 5% of the total volume of concrete and the thickness of optical fiber is lies between 2micron to 4mm. the volume and thickness of optical fiber depend on the purpose of light transmission or requirement of light transmission.

The optical fiber have three parts.

1. Core.

2. Cladding.

3. Buffer coating.

1. Core:- the center portion fiber where light travel is called core. the core diameter varies from 5 microns to 100 microns.

2. Cladding :- The outer optical material surrounding the core that reflects the light back into the core. To confine the reflection in the core, the refractive index of the core must be greater than that of the cladding.

3. Buffer coating;- buffer coating is a plastic coating applied over a cladding for the purpose of preventing the fiber from moisture and other damages.

Product | Light transmitting concrete |

Form | Prefabricated block |

Ingredient | 96% concrete, 4% optical fiber |

Density | 2100-2400kg/m2 |

Block size | 60cm*30cm |

Thickness | 25-500mm |

Colour | White, grey-black. |

Fiber distribution | Organic |

Finished | Polished |

Compressive strength | 50N/mm2 |

Bending tensile strength | 7N/mm |

Application:-

ü For decorative elevation.

ü Illuminate wall.

ü Get creative with a design.

ü Use in a pavement or load-bearing walls.

ü Increase visibility in a dark subway station.

ü Light fixture.

ü Use as transparent and decorative floors.

ü Light sidewalk at night.

ü In furniture for aesthetic view.

Advantages:-

ü When a solid wall is imbued with the ability to transmit light, it means that a home can use fewer lights in their house during daylight hours.

ü It has very good architectural properties for giving the good aesthetical view to the building.

ü Where light is not able to come properly at that place transparent concrete can be used. The main advantage of these products is that on large scale objects the

ü texture is still visible – while the texture of finer translucent concrete becomes indistinct at distance.

ü Energy saving can be done by the utilization of transparent concrete in building.

ü Totally environment friendly because of its light-transmitting characteristics, so energy consumption can be reduced.

Disadvantages:-

ü Casting of transparent concrete block is difficult for the labor so a special skilled person is required.

ü The main disadvantage is this concrete is very costly because of the optical fibers.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.